Evaporative Cooler for Belt Coaters & Coating Pans

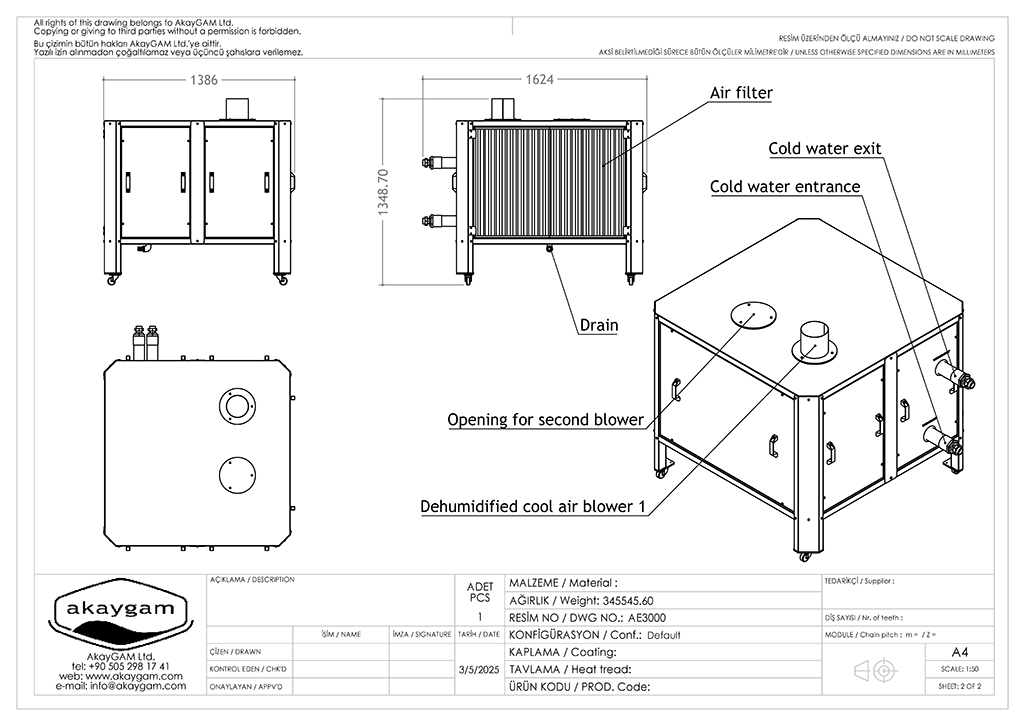

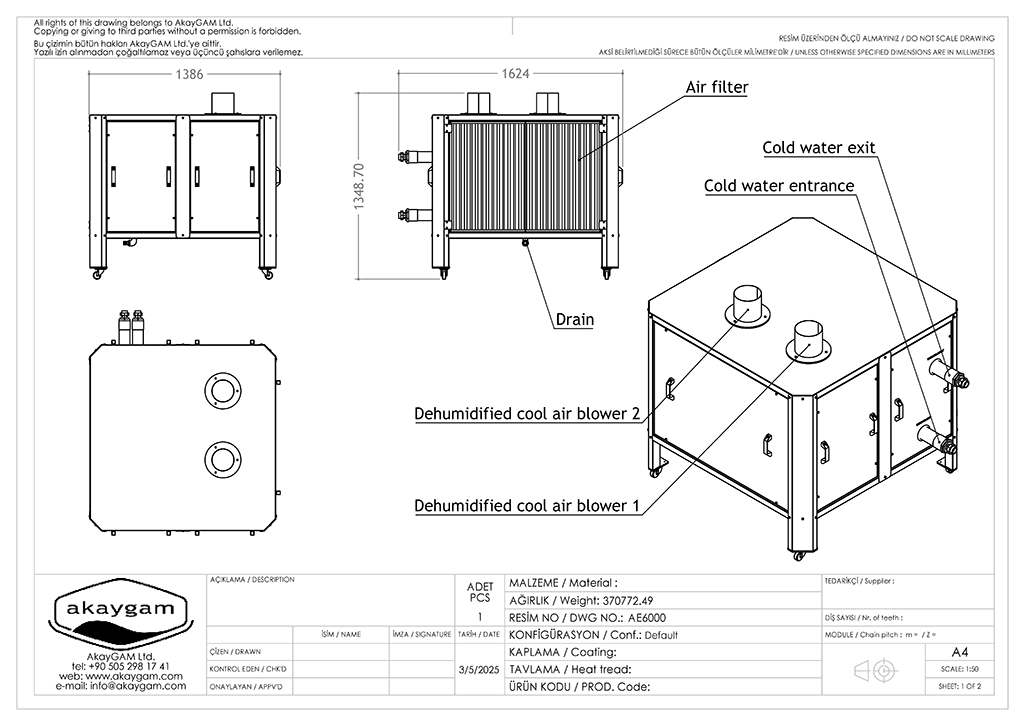

Insulated conditioned-air blowing unit with chilled-water coil, mist eliminator and air filter. Designed to supply cool, filtered air for chocolate panning and coating applications, helping stabilize the coating process and improve finish quality. The water coil is connected to an external chilled-water source such as a chiller.

Evaporative Cooler Models for Chocolate Coating and Panning

Standard configuration uses a single radial fan. A second radial fan can be added to increase airflow capacity and supply more coating stations.

Share

Evaporative Cooler for Chocolate Panning and Coating

The evaporative cooling device is an auxiliary piece of equipment for chocolate coating applications. It is designed to provide dehumidified cold air to a belt coater or coating pan. Provided conditioned air from the air cooling device will help to solidify the chocolate covered on the centers. The air conditioner for chocolate panning draws ambient air and delivers filtered, cooled, dehumidified air to the chocolate coating cabin. The evaporator should be connected to a chiller. It can supply cold air to a single coating cabin or two coating pans. The output of the air cooler has to be connected with a flexible aluminum hose to the hood of the belt coater or to the duct of the coating pan. By adding a second fan to the device, 4 coating pans or 2 belt coaters can be fed with cool air.

Related equipment

The air cooler can be connected with a flexible aluminum duct to the coating cabin's hood or to the coating pan's air supply pipe.