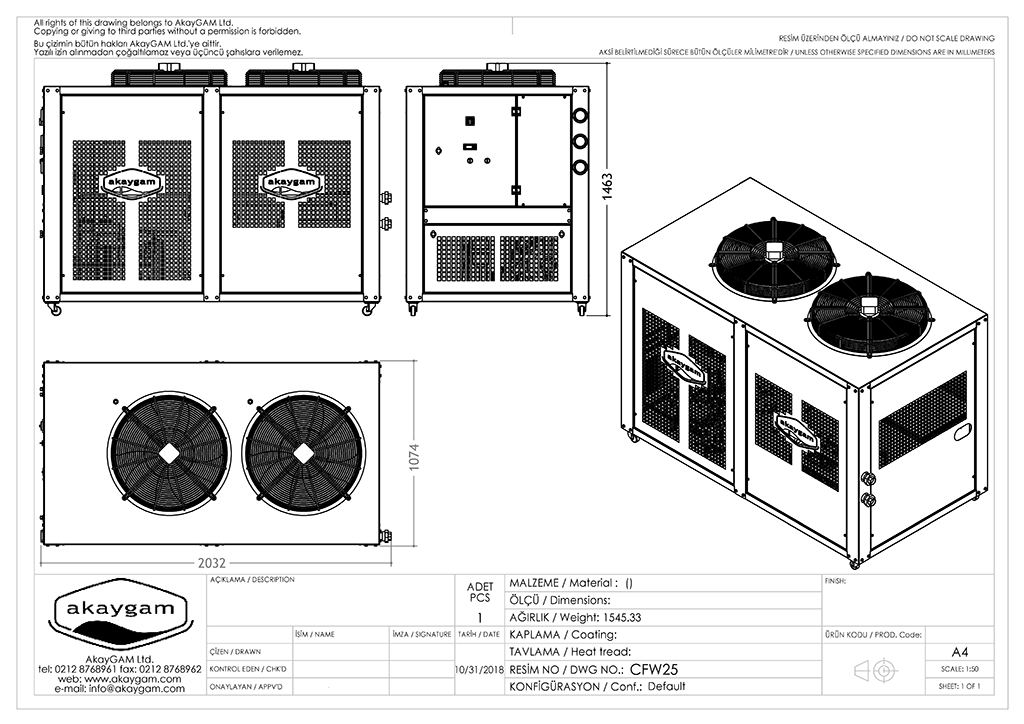

Chiller for Chocolate Machinery (CFW25)

Auxiliary equipment for cooling purposes. Supplies cold water/liquid to the ball mill refiner, forming drums of chocolate lentils forming line or heat exchanger, which is used for caramel cooling while transferring to a resting tank.

CFW25 Chiller for Chocolate Production

Chillers are used to maintain controlled product temperatures during mixing, grinding, kneading, transferring, and forming. The CFW25 is suitable for jacketed chocolate machines and plate heat exchangers where continuous cooling is required to keep process conditions stable and production results consistent.

Share

Applications of the CFW25 Chiller

The AkayGAM CFW25 chiller is an auxiliary cooling unit designed to deliver stable chilled water (or glycol mixture) to temperature-sensitive chocolate and confectionery equipment. It supplies cold liquid to jacketed systems such as the ball mill refiner, forming drums on the chocolate lentils forming line, and process heat exchangers used for caramel cooling. Consistent coolant temperature helps improve process stability, protects product texture, and supports repeatable quality during grinding, forming, and cooling operations.

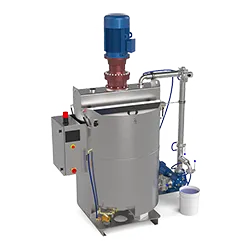

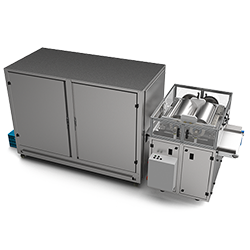

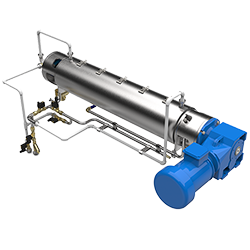

Related equipment

Above are devices: a ball mill refiner, chocolate lentils forming machinery and a heat exchanger to which the chiller can be coupled.