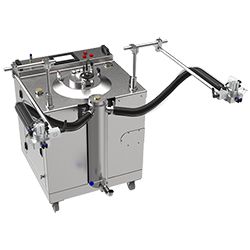

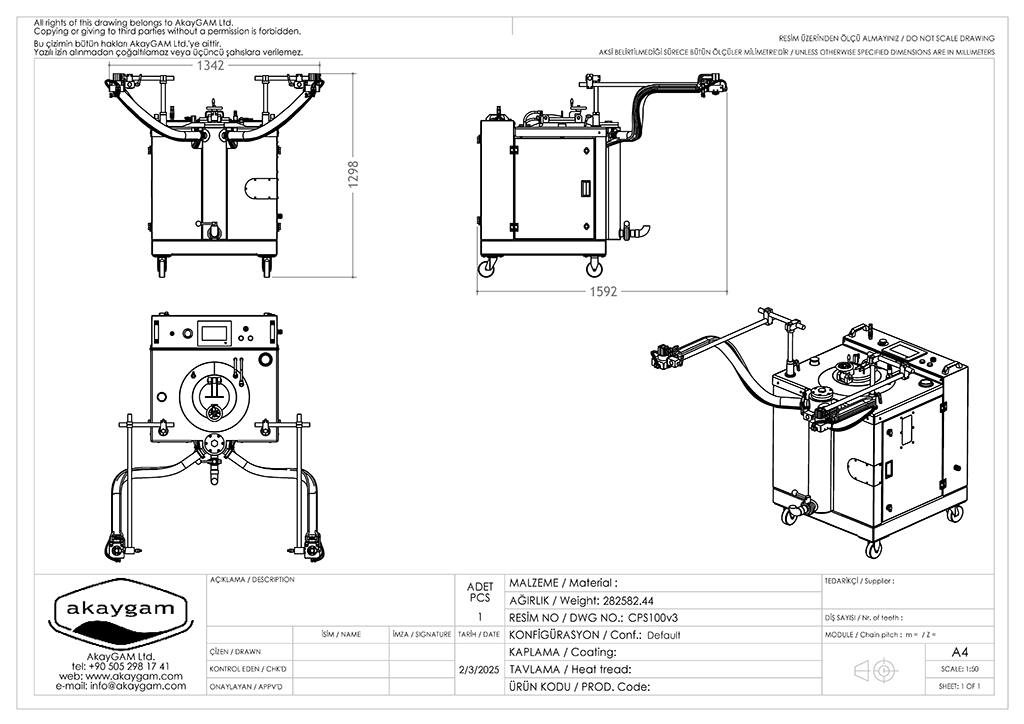

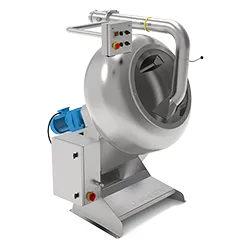

Automatic Chocolate Spraying Machine

The sprayer for coating pan is a device designed to automatically spray chocolate into the panning machine. Chocolate reservoir, flexible hoses, and the spraying nozzles of the machine are with heating control, ensuring that the chocolate inside the spraying machine remains liquid. Total spraying quantity, time to activate, and time to deactivate the chocolate feeding can be adjusted on the touch screen. The automatic sprayer can be used to spray sugar syrup as well.

VIDEO ITypes of chocolate sprayers for coating pans

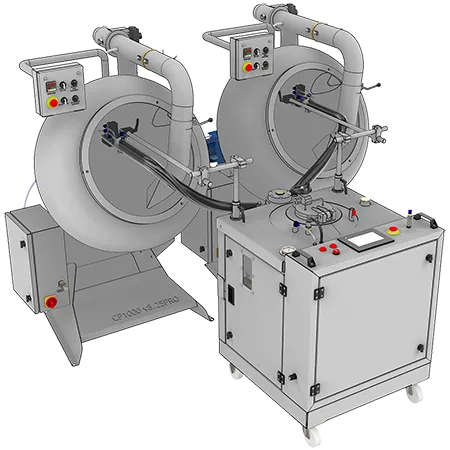

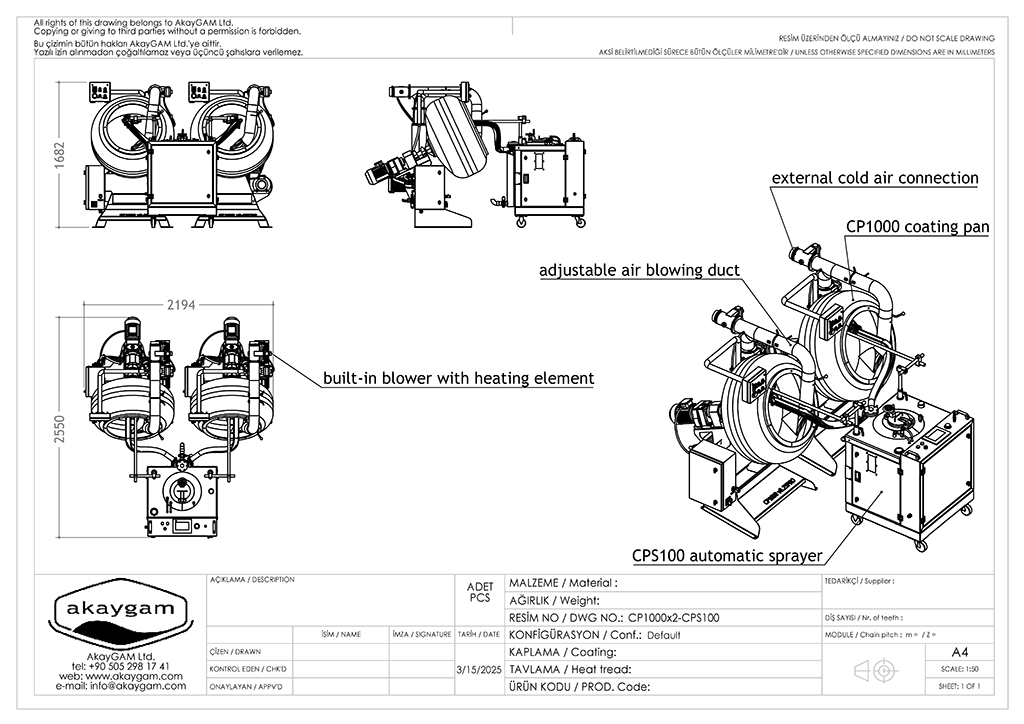

A second spraying unit can be easily coupled to the single spray nozzle machine that we produce as standard. With two spraying units machine can spray simultaneously on two coating pans.

Share

Description for chocolate sprayer

The chocolate spraying machine is designed to convert the chocolate coating process on coating pans from manual operation to automated. The machine pumps chocolate to the exit of the nozzle with the help of compressed air. To obtain clean compressed air, we recommend the use of a particle filter, a water separation filter, an oil separation filter and an active carbon filter. The sprayer is manually limited to maximum pressure by an air regulator. The allowed maximum pressure is limited to 4 bars. Thanks to the solenoid valve and the pressure transmitter, working pressure can be adjusted on touchscreen, machine will try to hold the pressure at the reservoir constant. The assembled level sensor will indicate a full or empty reservoir.

Reduce coating mistakes by automating the manual chocolate coating process in coating pans. Simplify the challenging panning, save your expenditures and standardize the finished product's coating rate.

Related equipment

The coating process on coating pans is normally done manually; however it can be mechanized. Use a chocolate sprayer to standardize results.