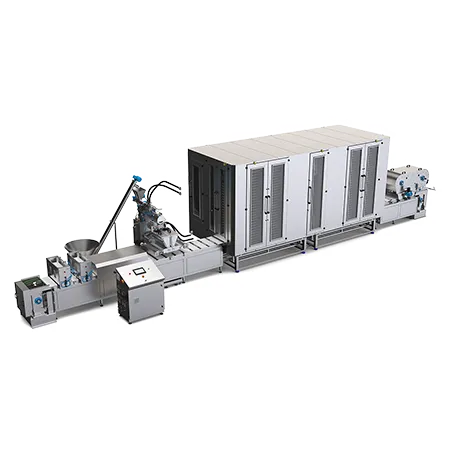

High Capacity Chocolate Molding Line (SML500)

This chocolate forming line is designed to make center-filled or plain chocolates using a one-shot chocolate depositor. It is equipped with sensors and a camera for inspection of mold faults, allowing it to automatically remove defective molds off the main conveyor and load clean molds onto it.

Because the line is completely automatic, we do not recommend utilizing transparent polycarbonate molds. Under the depositor, there is an infrared sensor that measures the temperature of the molds; if the mold is hotter than the acceptable temperature, the filling operation will not be performed, and the hot mold will continue all the way empty.

The requested mold dimensions are 205 × 600 mm.

VIDEO ITypes of chocolate molding lines

We produce chocolate production lines with elevator-type or horizontal cooling tunnels. We produce chocolate shell lines as well.

Share

Description for chocolate molding line

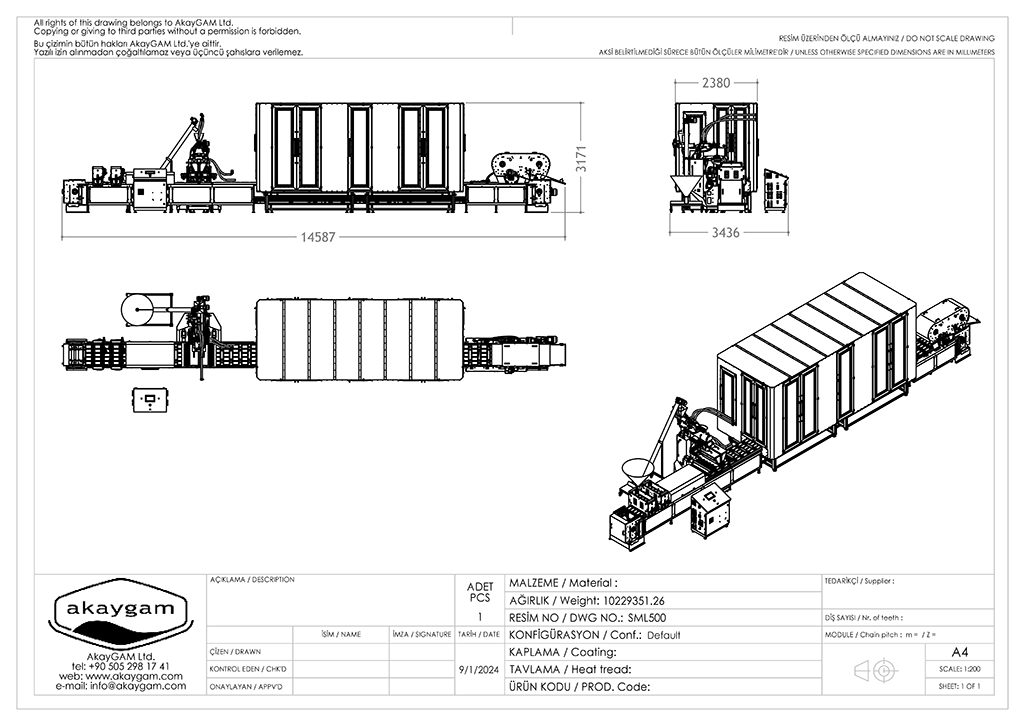

SML series line with a capacity of up to 500 kg/h. and demolding function. Designed for medium-sized chocolate manufacturers. Cooling tunnel is an elevator type. To save a substantial amount of space, the main conveyor is a bottom loop type rather than a side loop type. The molding machine is equipped with camera for mold inspection, so we recommend using green or blue-colored molds, as transparent molds are incompatible for the camera and sensors. Line is designed especially for center-filled (fat-based) molded chocolate manufacturing. Different working styles of the chocolate filling machine are installed inside the PLC and they are selectable on HMI. As the depositor is a one-shot type, using crushed nuts or crunch are not allowed.

Auxiliary equipment

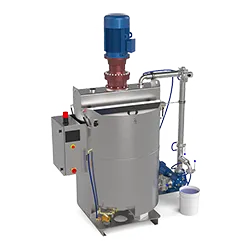

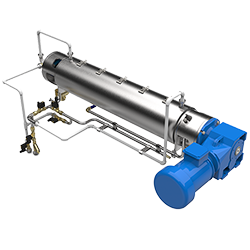

A ball mill is required for the refining process of the chocolate ingredients. Storage tank is equipment to hold chocolate in a homogeneous and liquid condition. Decrystallization tube's main function is to prevent thermal fluctuations inside the storage tank.

Frequently Asked Questions

Quick answers about the SML500 high-capacity chocolate molding line, molds, cooling, capacity, and support.

What products can the SML500 molding line produce?

The SML500 is designed for plain molded chocolates and center-filled molded chocolates. It is especially suitable for filled products where stable temperature control, mold handling, and repeatable depositing are required.

What is the production capacity of the SML500?

Typical capacity is 300–500 kg/h, depending on total weight per shot, and time settings of the line are key factors affecting output.

Which mold size is supported?

The line is configured for 205 × 600 mm polycarbonate molds.

Why are transparent molds not recommended?

Because the line uses sensors and camera-based mold inspection, transparent molds can reduce detection reliability. For stable inspection and rejection performance, green/blue polycarbonate molds are preferred.

How does mold inspection and rejection work?

The line checks molds with sensors and a camera. If a mold is unsuitable for filling, it can be automatically rejected from the main conveyor and replaced with an acceptable mold to keep production stable.

What type of cooling tunnel is used?

The SML500 uses an elevator-type cooling tunnel to save floor space.

See also: Cooling tunnels.

Can the line run with crunchy inclusions (nuts, crispies) in the filling?

For this configuration, the depositor works as a one-shot type, so crushed nuts or crunch inclusions are not recommended because they can block the dosing path and reduce deposit accuracy.

What utilities are required?

A typical configuration is 380V / 3-phase with total power around 25 kW. Requirements can vary depending on options (cooling, air conditioning, automation), so we confirm utilities during quotation.

Which upstream equipment is typically used with a molding line?

For stable molding, chocolate should be refined, stored, and tempered before depositing. A typical setup includes:

- Ball mill for refining

- Storage tank to keep chocolate homogeneous and liquid

- Decrystallization tube to stabilize temperature and reduce thermal fluctuations

- Tempering machine for gloss and stable crystallization

Do you provide installation, commissioning, and training?

Yes. Depending on project scope and location, we can support commissioning and operator training remotely and/or on-site. We focus on safe start-up, parameter setting, and stable production.