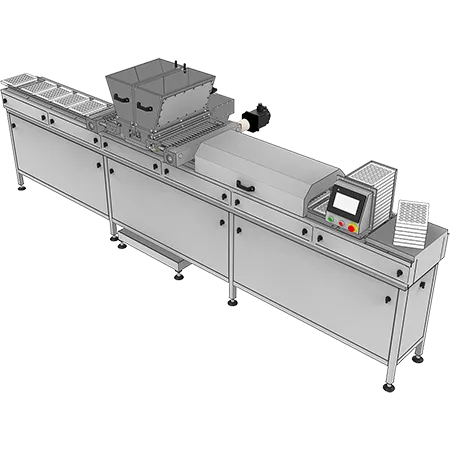

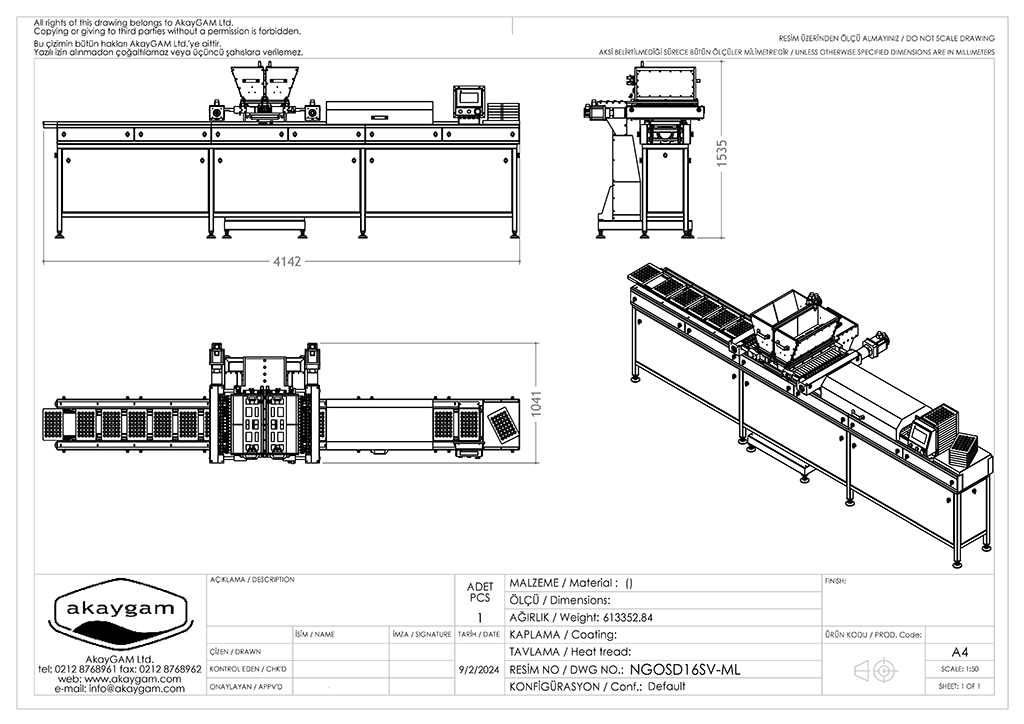

Chocolate Molding Machine

This is equipment that is used to produce molded center-filled chocolates. A crunch feeding device and a second depositor can be added to the mold conveyor. The machine includes a mold loader, mold heater, depositor, mold vibration and mold conveyor. Demolding is done manually because this type of machinery is unsuitable for mold looping. Cooling tunnels can be automatically fed with pre-filled molds, but demolding and loading the mold feeder is a human process.

VIDEO ITypes of chocolate depositors with conveyors

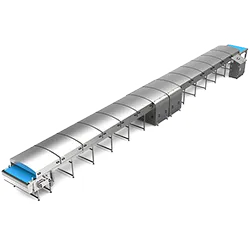

We produce semi-automatic chocolate making lines with elevator-type or horizontal cooling tunnels.

Share

Description for the simple chocolate molding line

The capacity of the machine depends on the outpoured weight per shot, speed adjustments of the filling and conveying. Capacity may vary between 200-500 kg/h. Equipment can perform maximum 20 shots per minute. Designed for medium-sized chocolate manufacturers. If the cooling tunnel is horizontal then it should be with rods or modular belt conveyor so the product can be cooled equally from the top and bottom. The chocolate cooling tunnel is coupled perpendicular to the polycarbonate mould flow of the molding machine.

Specially designed for center-filled (fat-based) molded chocolate manufacturing. Single working style for the filling machine. As the depositor is a one-shot type, using crushed nuts or crunches is not allowed.

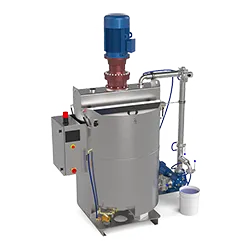

Auxiliary equipment

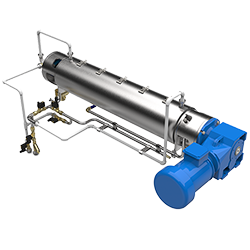

A ball mill is required for the refining process of the chocolate ingredients. Storage tank is equipment to hold chocolate in a homogeneous and liquid condition; it is used to feed the tempering machine, which will form the crystal structure of the chocolate. Decrystallization tube is used to break the crystal structure of tempered chocolate at the bypass line.