Industrial Chocolate Processing Machines & Production Lines

At AkayGAM, chocolate machinery is engineered with a process-first mindset. We use a structured 3D standard parts library and Excel-based design automation script to shorten development time, standardize components, and improve manufacturing repeatability. This approach supports faster engineering cycles, controlled purchasing, and consistent machine performance across projects.

Each machine is designed digitally, validated for production, and optimized for hygienic construction, mechanical durability, and long-term industrial reliability.

Our YouTube ChannelChocolate Machines by Category

Browse AkayGAM chocolate processing machines grouped by process stage.

Chocolate Preparation

Melting, refining, mixing, and storage equipment for chocolate mass and confectionery bases.

Chocolate Forming

Molding lines, depositors, and cooling solutions for industrial chocolate production.

Chocolate Coating

Chocolate coating systems for centers, bars, cookies and nuts: belt coating, enrobing and panning.

Chocolate Processing Machinery Manufacturer – AkayGAM LLC

Headquartered in Istanbul, Turkey, AkayGAM LLC has been designing and manufacturing industrial chocolate processing machinery for over 20 years. Our production facilities have expanded from a 450 m² workshop to a modern 1,200 m² manufacturing plant, supporting in-house fabrication, assembly, and testing.

All machines are produced under controlled manufacturing procedures, using food-grade stainless steel and standardized fabrication methods.

Process-contact parts are manufactured in AISI 304 stainless steel as standard, with AISI 316 available for specific applications. Electrical panels and automation systems can be configured according to regional standards, voltage and frequency requirements, and preferred PLC/HMI platforms. Where applicable, equipment is prepared for CE conformity in accordance with relevant European directives.

Control systems can include PLC-based recipe management, temperature logging, and real-time production parameter monitoring depending on project scope and automation level.

AkayGAM machines are supplied to customers across Europe, the Middle East, and other international markets, with export documentation and remote support available where required.

Machines for Every Stage of Chocolate Production – From Startup to Industrial Scale

Many chocolate producers begin with entry-level equipment to validate recipes and market demand. As production increases, limitations in capacity, temperature stability, and repeatability become more visible.

Some manufacturers experiment with low-cost machinery to reduce investment, but this often results in higher maintenance needs, inconsistent results, and unplanned downtime.

AkayGAM machines are designed to bridge this gap—offering robust construction, controlled thermal management, and scalable automation without unnecessary complexity. This allows producers to grow capacity while maintaining predictable quality and manageable operating costs.

Each machine category below addresses a specific stage in this growth path, allowing producers to scale capacity without redesigning the entire process.

Why AkayGAM LLC?

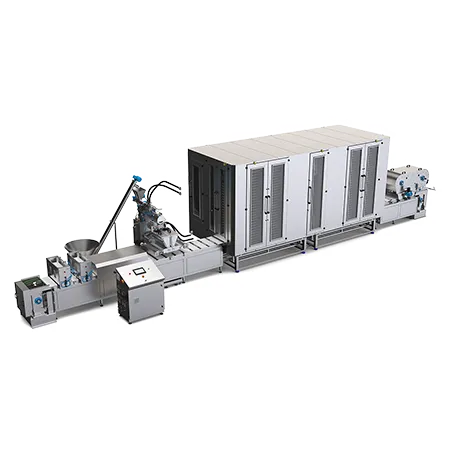

High-Capacity Fully Automatic Chocolate Molding Line (Up to 500 kg/h)

The SML500 is engineered for continuous molding of chocolate bars, tablets, and pralines at production rates up to 500 kg/h. The line operates with 205 × 600 mm polycarbonate molds and integrates filling, vibration, cooling, and demolding in a synchronized workflow.

Camera-based mold inspection supports automatic rejection, with green or blue molds recommended for reliable detection. The system is optimized for continuous operation in medium and high-throughput production environments.

Explore our high-capacity molding line for bars, tablets, and pralines.

View Machine DetailsShare

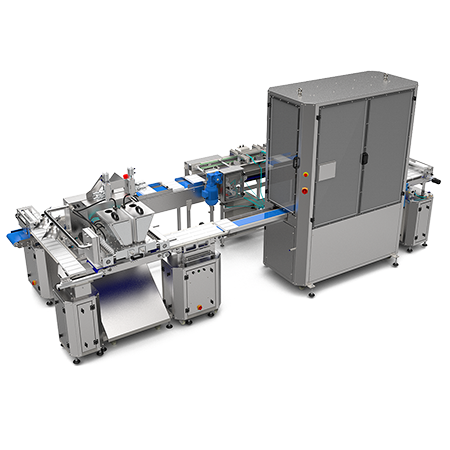

Compact Fully Automatic Mini Chocolate Molding Line (Up to 200 kg/h)

Our compact mini chocolate molding line offers throughput up to 200 kg/h, making it ideal for small and medium-scale chocolate manufacturers. It is built for 175 × 275 mm polycarbonate molds and delivers consistent molding performance while saving valuable floor space.

See the compact automatic chocolate molding system designed for space-efficient production.

View Machine DetailsShare

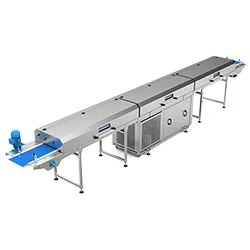

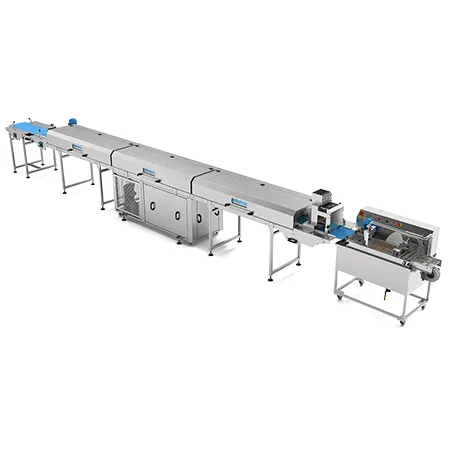

Chocolate Enrobing Line for Bars, Cookies & Wafers (Up to 100 kg/h)

Our chocolate enrobing line operates at rates up to 100 kg/h, making it an excellent choice for small to medium-scale producers coating cookies, wafers, snack bars, and confectionery centers. The system includes a 200 mm enrobing belt, a wheel-based tempering machine, and an optional sprinkling unit to ensure smooth coating, uniform thickness control, and professional finishing quality.

Learn more about the chocolate enrobing line for coating bars, cookies, wafers, and confectionery centers.

View Machine DetailsShare

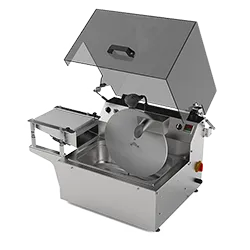

Automatic Chocolate Belt Coater (BTC Series) for Nuts & Confectionery Centers

The AkayGAM BTC Series Belt Coater delivers uniform chocolate coating for nuts, candies, biscuits, and confectionery centers. Developed for medium to large-scale production, it is efficient, easy to clean, and engineered for uniform coating thickness with controlled airflow and regulated chocolate circulation.

Discover our automatic horizontal chocolate coating machine designed for nuts, candies, biscuits, and confectionery centers.

View Machine DetailsShare

Frequently Asked Questions

Quick answers about AkayGAM chocolate machines, production lines, lead time, and support.

Do you manufacture chocolate machines in Turkey?

AkayGAM manufactures industrial chocolate processing machines in Istanbul, Turkey, and supplies equipment internationally. Machines are built using food-grade stainless steel under controlled fabrication procedures.

See categories: Preparation, Forming, Coating, and Other machines.

Do you ship chocolate machinery worldwide?

AkayGAM supplies chocolate machines worldwide. Export scope may include documentation, remote support, and commissioning assistance depending on project size and destination.

Can you build complete chocolate production lines?

We support complete line planning from raw material melting to final molding or coating and cooling. We recommend machines based on your product, capacity, and layout constraints.

Do you provide installation and training?

Depending on project scope and location, we can support commissioning, operator training, and after-sales service. Support can be remote and/or on-site for larger lines, focusing on safe start-up, parameter setting, and repeatable production cycles.

What information do you need to recommend the right machine?

To recommend the best solution, we typically need:

Send these details through Contact Us and we will reply with suitable machine options.

Do you customize machines (voltage, PLC/HMI, capacity)?

Many models can be configured for different capacities, electrical standards, and automation options.

Examples: tempering machines, ball mill refiners, belt coaters, and cooling tunnels.

What is the typical lead time and how can I get a quotation?

Lead time depends on machine type, capacity, and configuration. After you share requirements, we confirm scope and delivery schedule in the quotation. For a faster quotation, include your country, voltage/Hz, product type, and required capacity.

Use Contact Us to request a quotation.

Which machines do I need to start a small chocolate production?

A typical starter setup depends on the product, but many producers begin with:

Tell us your product and target output, and we’ll suggest the best configuration.