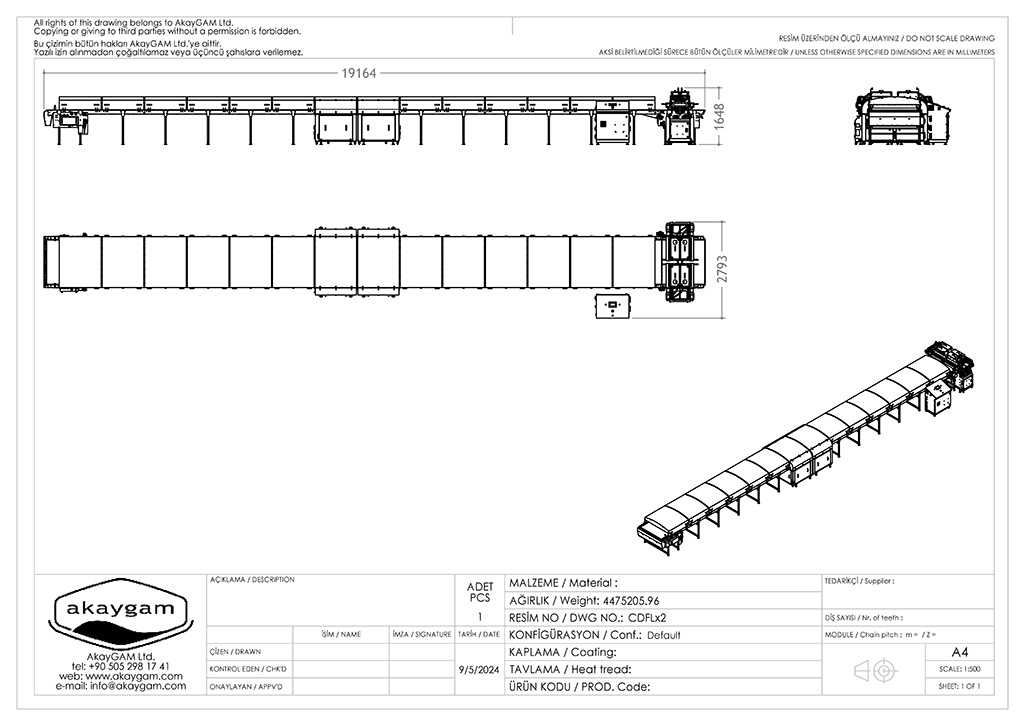

Chocolate Drop Line (CDFLx2)

Real or compound chocolate; drop production line with capacity up to 60,000 drops/min. or 15,000 chips/min. Dripping directly onto the polyurethane belt of the horizontal cooling tunnel.

VIDEO I VIDEO II VIDEO III VIDEO IVTypes of chocolate drops, chips dripping lines

We produce lines with one or two depositors. The cooling tunnel's length can vary between 14 and 25 mt. If the line is going to be used only for chocolate drops manufacturing, then the cooling length can be 14 mt. however, chocolate coins manufacturing will need a longer cooling coneyor.

Share

Description for chocolate coins dripping line

Pouring of chocolate directly onto the cooling tunnel's belt. The tunnel is with two cooling zones. Depositors are with servo-driven vertical motion and PID-controlled dry heating. Completely PLC and HMI operated. Line is suitable for compound or real chocolate. Chocolate depositors are optimized for chocolate drops and chips manufacturing. Depending on the speed and distance settings, equipment can perform up to 20 shots per minute.

Auxiliary equipment

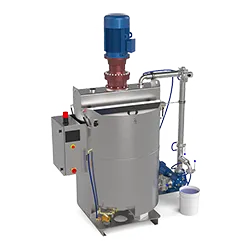

A ball mill is required for the refining process of the chocolate ingredients. The storage tank is equipment to hold chocolate in a homogeneous and liquid structure; it is used to feed the tempering machine, which will form the crystal structure of the chocolate.