Automatic Chocolate Panning - Belt Panner

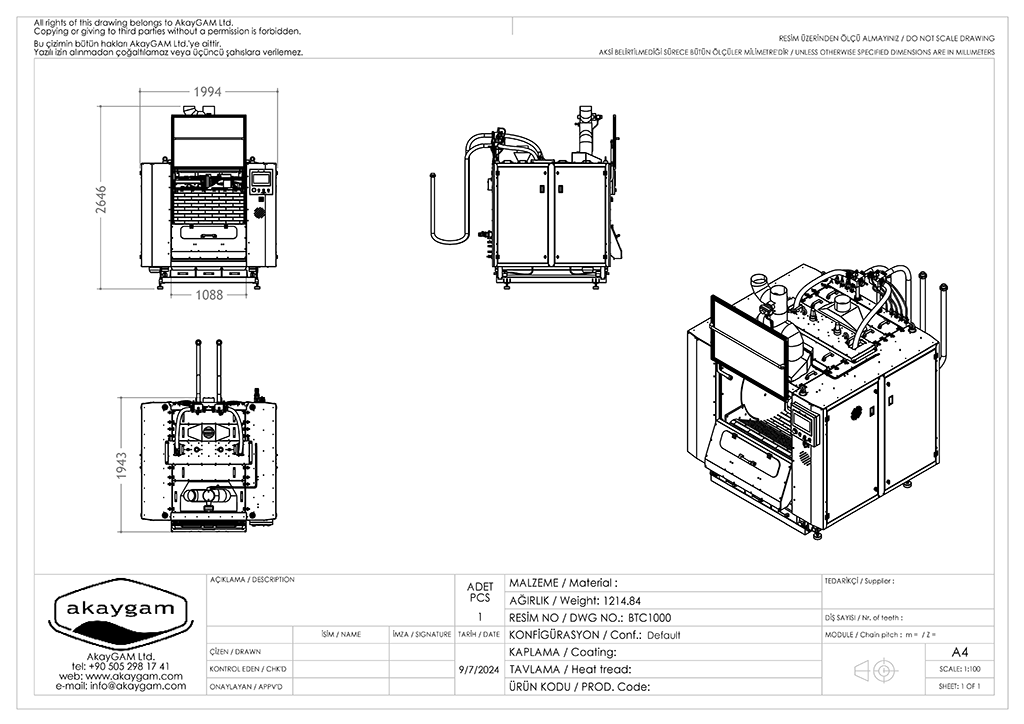

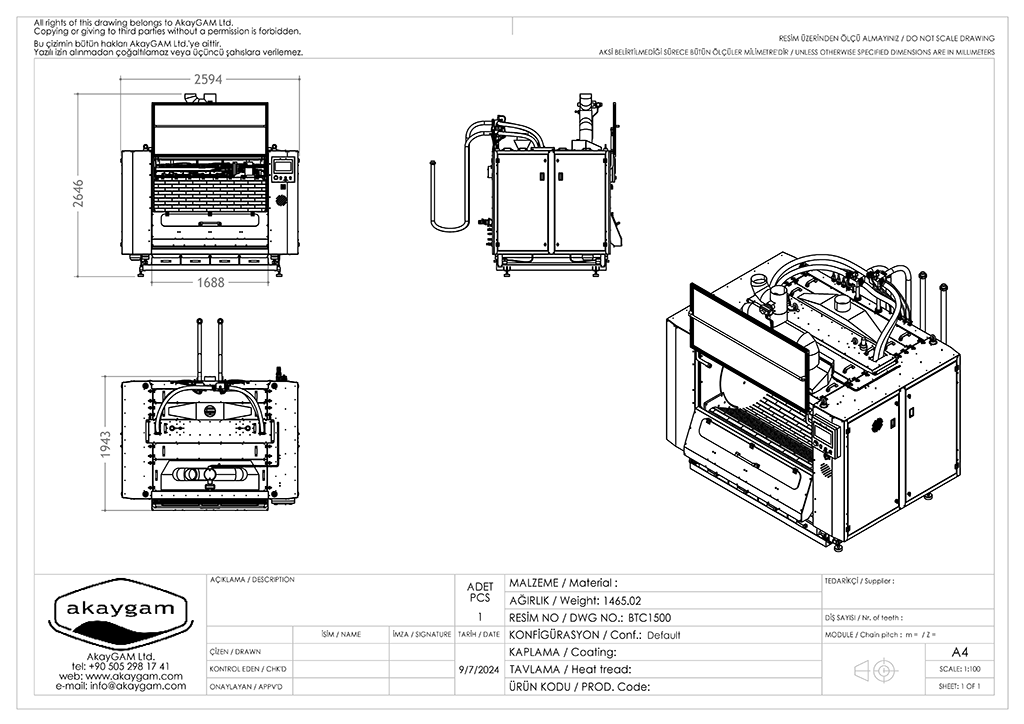

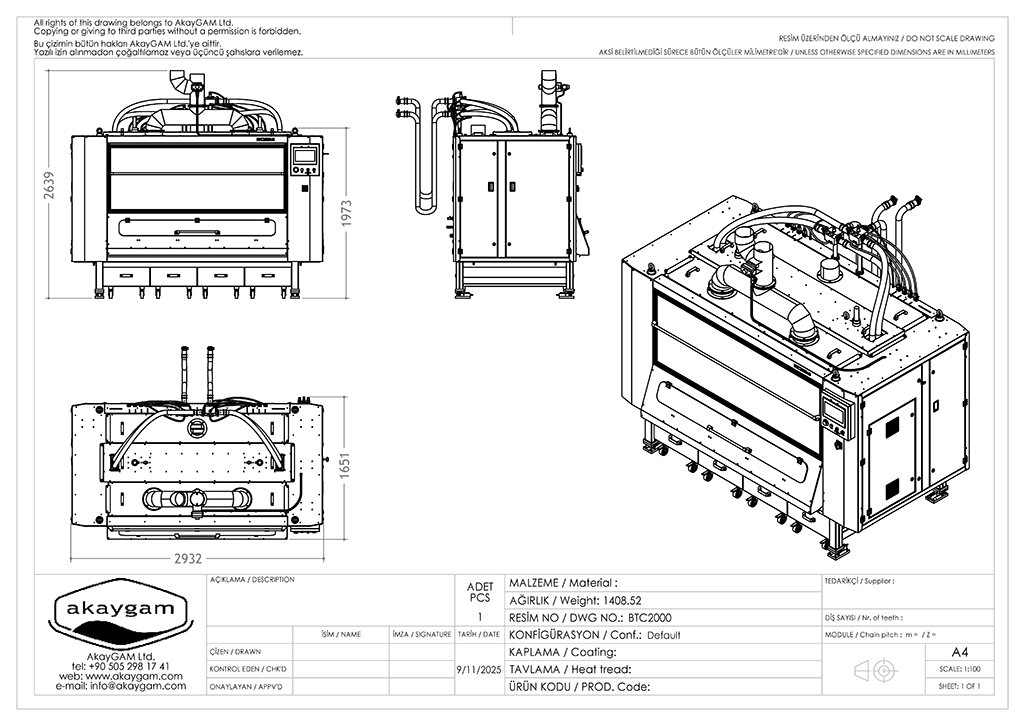

Automated device for producing chocolate-coated nuts. Belt coaters are large-scale panning machines that replace traditional coating pans. Designed for those who want to automate their chocolate engrossing process.

VIDEO I VIDEO IITypes of automatic chocolate coaters

We manufacture automatic engrossing machines for small workshops and medium-sized confectionery producers.

Share

Description for automatic chocolate engrossing

Coating cabin is an automatic chocolate panning machine. It is used to cover various centers with chocolate, chocolate-flavored compounds or other fat-based liquids. All kinds of articles with shapes capable of being rolled can be coated with chocolate by using the belt panner. The chocolate pouring body of the machine is capable of spraying or dripping chocolate onto the centers. Chocolate spraying nozzles are used for engrossing lightweight centers like puffed rice and cereals. Dripping body, chocolate distribution bodies and flexible hoses of the coating cabin are with PID-controlled heating elements. Dripping body and chocolate pump are equipped with pressure transmitters to prevent damages related to overpressure.

Auxiliary equipment

To accelerate the solidification of the chocolate layer, dehumidified cold air should be connected to the coating cabin's hood. We produce chiller and evaporator suitable to be used for the cooling purpose of the belt coater. A storage tank with a pump has to be connected to the dripping body of the chocolate coating machine.

Advantages of belt-type chocolate panning technology

Traditional pans are the most common equipment in use, but the requirement of a skilled operator and the difficulty of unloading coated centers prompted confectionery manufacturers to seek new methods of chocolate coating.

The belt coater is designed to eliminate the disadvantages described above of coating pans and to meet the new requirements of the industry. This type of coater is very easy to use, as the wide opening allows easy loading of articles. Unloading is performed by simply reversing the direction of belt rotation. The belt coater is equipped with a heated chocolate-dripping body and load cells and it is operated by a PLC which automates the coating process.

Belt coaters are becoming more and more common in the candy industry. The efficiency, ease of use, high production capacity and automation of the new coating technology make them an attractive alternative.