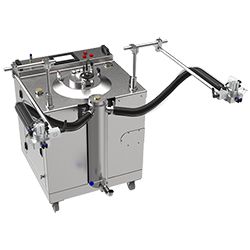

Coating Pan (Chocolate Panning Machine)

Manual panning machines are used for sugar syrup coating, chocolate coating and polishing purposes. To prevent the product from spinning, revolving pans used for glazing should have ribs within.

VIDEO I VIDEO IITypes of coating pans

Beside revolving pans for product development or laboratory use, we produce machines for small workshops and medium-sized confectionery manufacturers as well.

Share

CP400 coating pan - technical features

VIDEODescription for manual panning machine

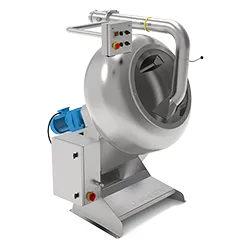

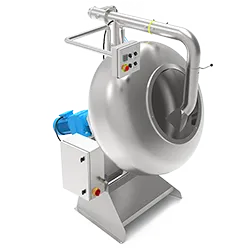

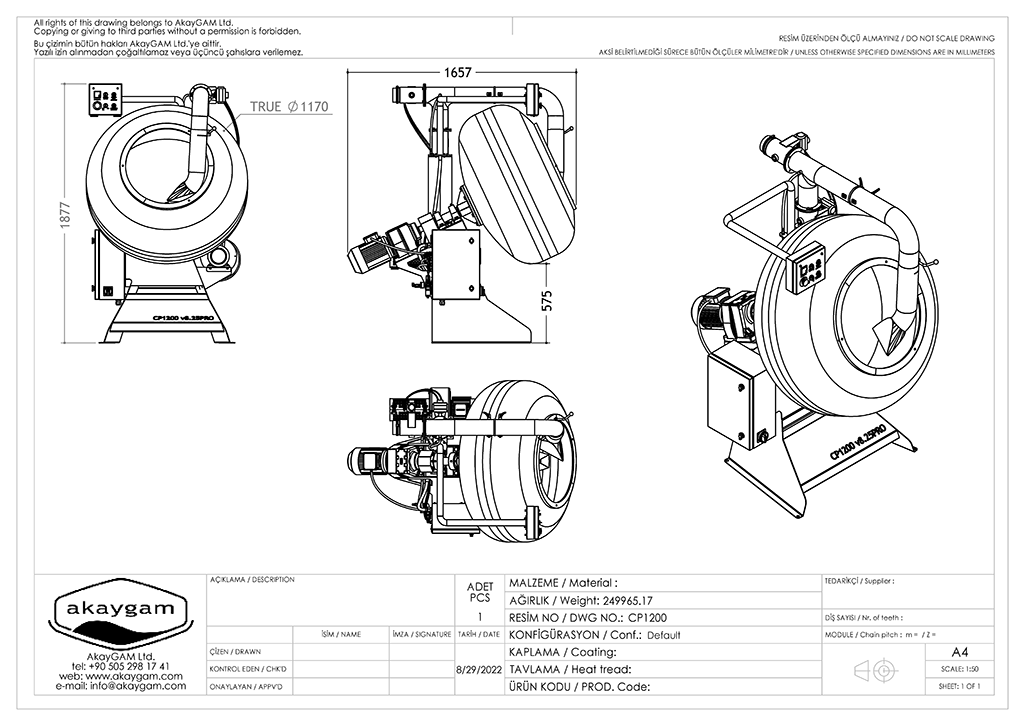

Coating machines are used to coat confectionery centers or roasted nuts with candy shell or chocolate. The rotation speed of the pan can be adjusted via VFD. PID-controlled air heating element and a blower can be assembled to the machine. Hot air blowing serves for product smoothing; it also helps to melt the chocolate layer on the pan, thus making the pan easy to clean. The blower's air flow rate can be adjusted via dimmer. Flexible flat end for the air blowing inside the pan. We recommend using a ribbed pan to be used for the polishing cycle, as sliding is expected while revolving. Ribs inside coater will assist the product to roll.

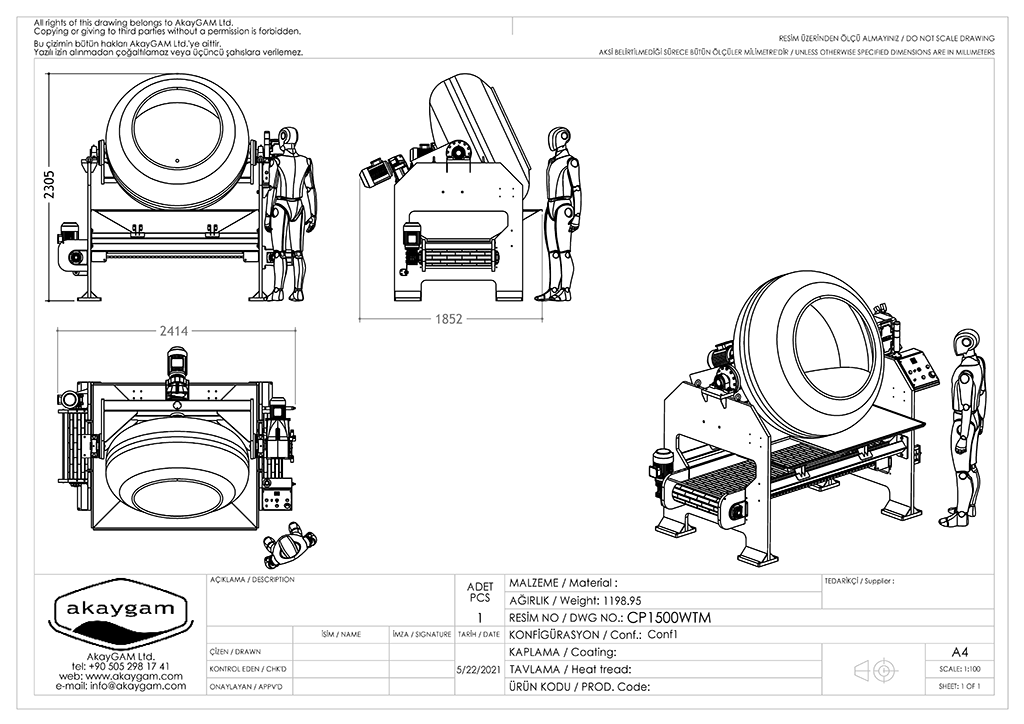

The CP1500WTM pan is usually used for coating of high or low-density centers like; cocoa lentils, hazelnuts, pistachios, crispy rice and similar. The CP1500WTM device is equipped with a tilting mechanism that allows easy discharging and a variable working angle. The machine is equipped with adjustable limit switches and a working angle switch. The working angle switch will allow each time to stop on the required angle when engrossing is going to be performed. The limit switches will prevent any crashes to the machine's other components and will allow you to cease discharging at the same angle every time. Pan is equipped with a VFD (variable frequency drive) and its acceleration and deceleration time is tuned to protect sprockets inside the gearbox against damage. Stainless steel or painted black steel frame.

Coat nuts and confectionery centers using fully AISI 304 stainless-steel coating pans.

Related equipment

Coating on coating pans is a human procedure; however, it can be automated. To obtain the desired result, use a chocolate sprayer. The assembled blower draws ambient room air and blows it into the coating pan. To boost the efficiency of the coating process, we propose employing a dehumidified cool air-blowing box and a chiller.

About traditional panning

Panning is a coating process of centers with layers of sugar syrup, chocolate, compound or yogurt in a coating pan. The coated article can be almonds, peanuts, hazels, raisins, malted milk balls, cherries, preserved gingers or nougat. The article must have some solidity; otherwise, it will break in the panning machine while rotating.

The chocolate coating process flows in three separate operations.

Preglazing is a coating process of a thin syrup layer that will seal the centers and prevent the mixing nut oil to chocolate. Mixing the nut oil into the chocolate coating will develop fat bloom or will soften the chocolate coating. However, the preglazing operation can be bypassed in case a thick chocolate coating is going to be applied.

While centers are rotating in the pan, syrup of 50 percent concentration is poured in small quantities. Pan rotation will allow distribution of the syrup over the surface of the nuts and blown air onto the syrup layer will cause it to dry out as a glaze. It is necessary to dry out each layer before pouring the next syrup. The syrup used for preglazing should be viscous and not crystallize after drying.

To increase viscosity, gum arabic can be added. To reduce crystallization, glucose syrup may be used.

Some confectionery manufacturers are using dusting powders to build up the glazing layer. Dusting powder consists of cocoa and powdered sugar mixtures. Using dusting powder for glazing is particularly useful when preserved fruits or ginger are being panned, as it helps to neutralize the stickiness of the liquid glazing solution.

Engrossing is the chocolate coating operation. The chocolate used for coating should be fluid enough so it can be easily distributed over the articles being coated. To build up the chocolate layer, about 13 degrees of cool air with humidity at 60 percent or below should be blown inside the pan. Care is required in this operation to prevent adhesion of the centers.

Final glaze can be obtained by various methods, but basically, for the best result, two distinct layers are applied: first is a syrup glaze and the second a wax or shellac glaze. The syrup glaze is similar to the one used for preglazing or edible dextrin may be used. To make the syrup viscous "crystal gums" may be used instead of gum arabic. The syrup glaze is applied by pouring two or three layers with drying in between. Cold air about 18 to 21 degrees and humidity about 50 percent is blown inside the pan to dry the syrup. The drying is continued until all signs of stickiness have disappeared.

After this glazing operation, the product should be left for resting at least for 12 hr. in a conditioned room at about 18 degrees and a humidity of 50 to 60 percent. After this period of drying, the second final glaze wax or edible shellac glaze is applied again inside the pan.

The wax glaze may be beeswax or carnauba wax and the final product obtains a dull glaze. For a glossy surface, it is necessary to use varnish prepared from shellac.