Chocolate Ball Mill Refiner (Lab & Industrial Models)

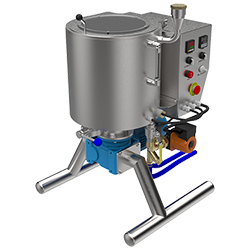

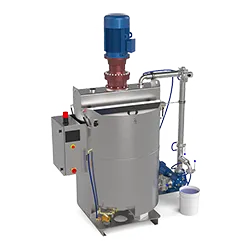

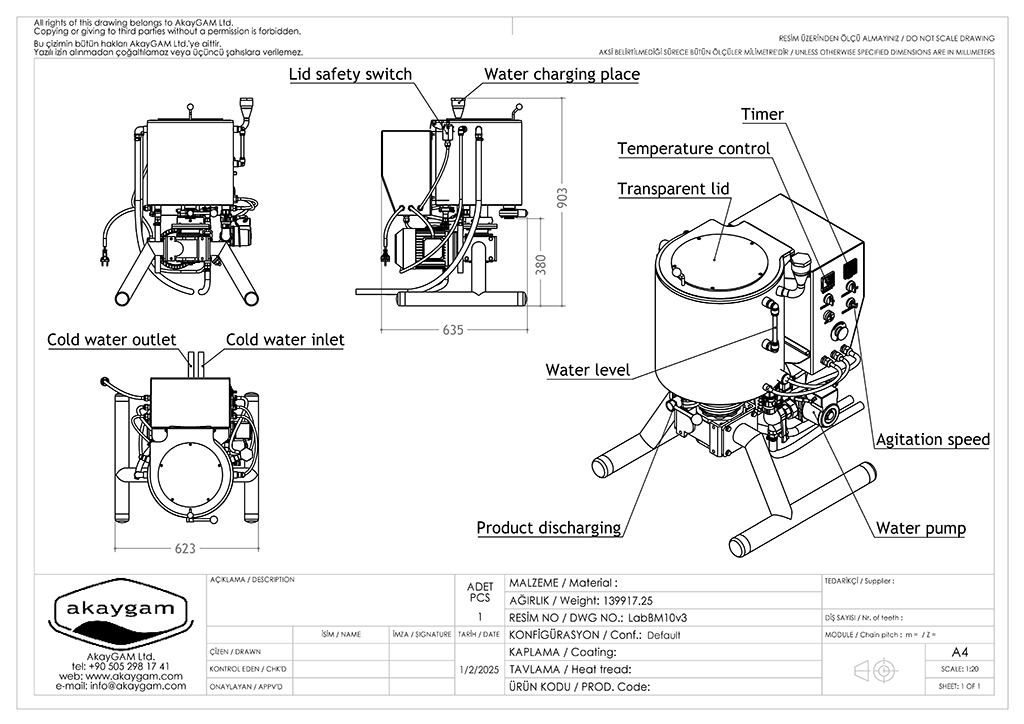

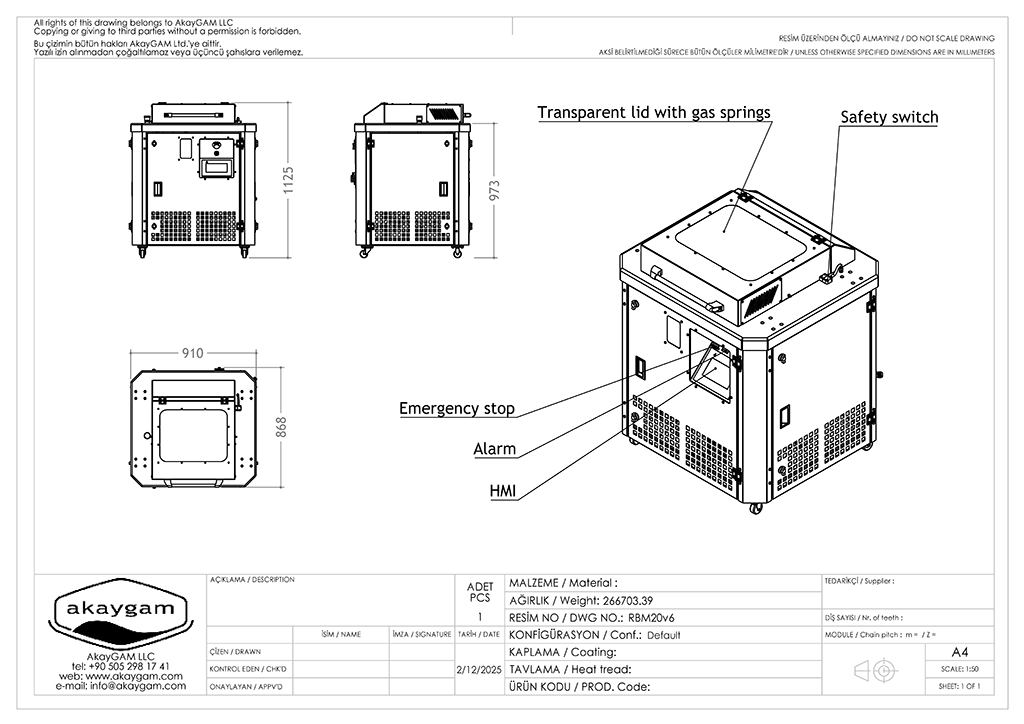

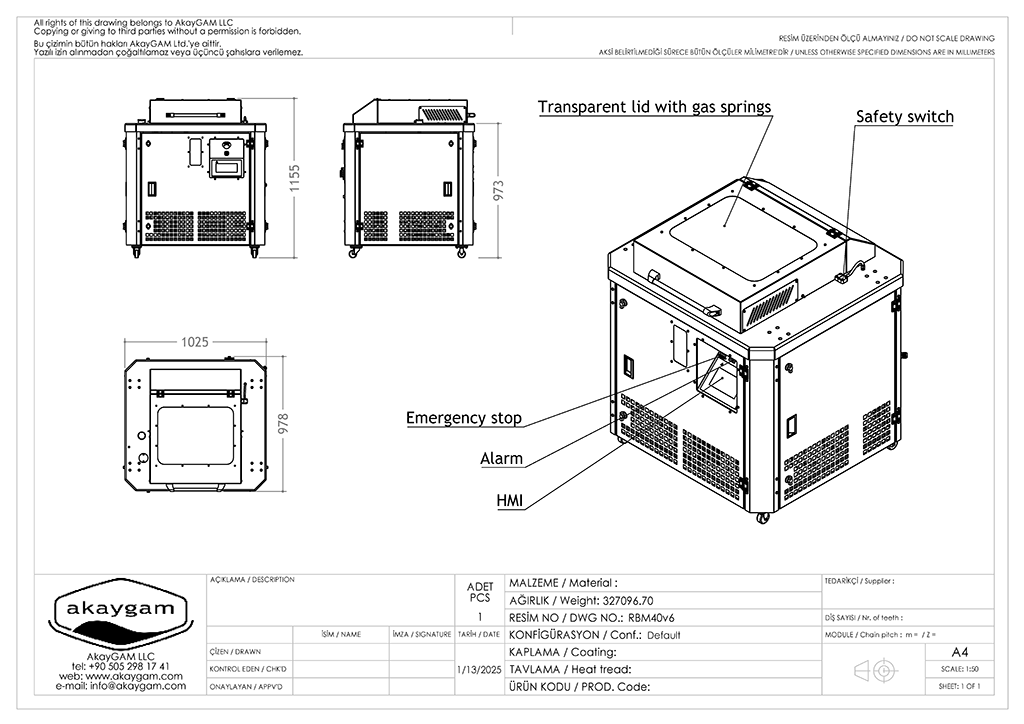

AkayGAM ball mill refiners are batch-type grinding machines designed for chocolate, nut spreads, creams, and tahini recipes containing at least 30% fat. Depending on refining time and recipe, the final particle size can reach as low as 18 microns for a smooth, premium texture.

VIDEO I VIDEO IIBall Mill Refiners for Lab, Artisan & Industrial Production

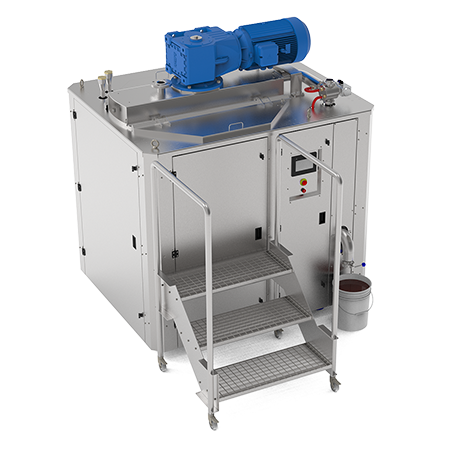

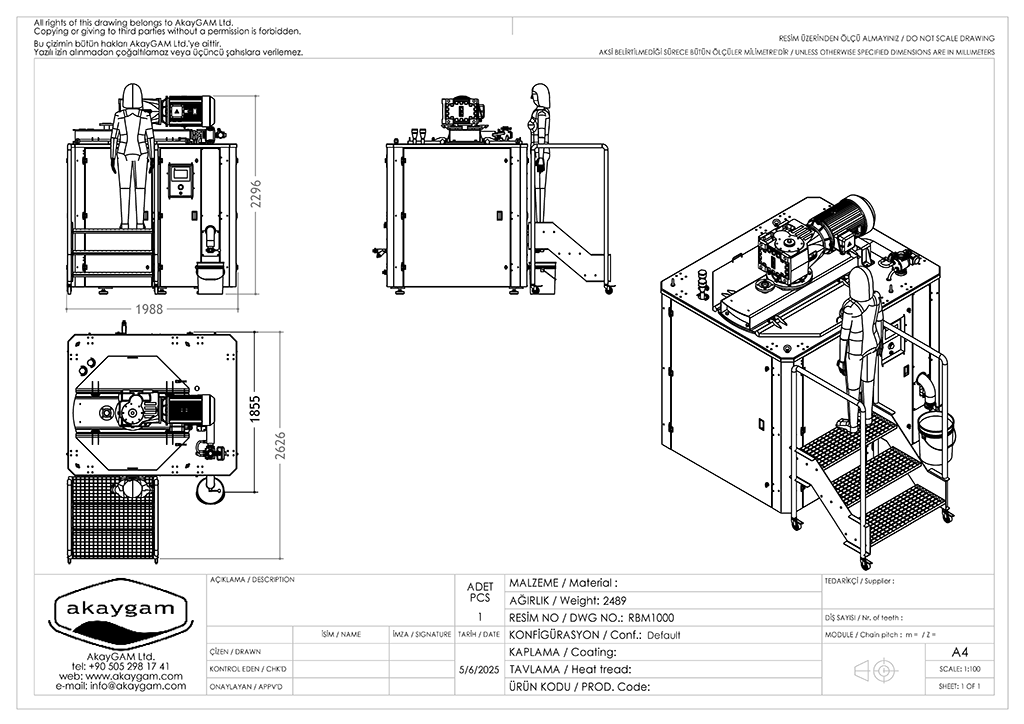

From product development labs to small workshops and medium-sized confectionery manufacturers, our range covers 15-1000 kg batch capacities with reliable temperature control and consistent refining performance.

Share

How a Chocolate Ball Mill Refiner Works

A chocolate ball mill refiner reduces particle size by grinding the product between thousands of hardened steel balls inside a rotating refining tank. As the mixing arms move the chocolate mass through the ball charge, solid particles are gradually broken down into a fine and smooth texture suitable for premium chocolate and nut spreads.

Unlike dry milling systems, ball mill refining is designed for fully fluid recipes. For stable operation, the mass should contain enough fat (typically at least 30%) so it can circulate properly and prevent excessive viscosity. During refining, both particle size and the overall mouthfeel improve progressively, allowing producers to reach their target fineness depending on recipe and processing time.

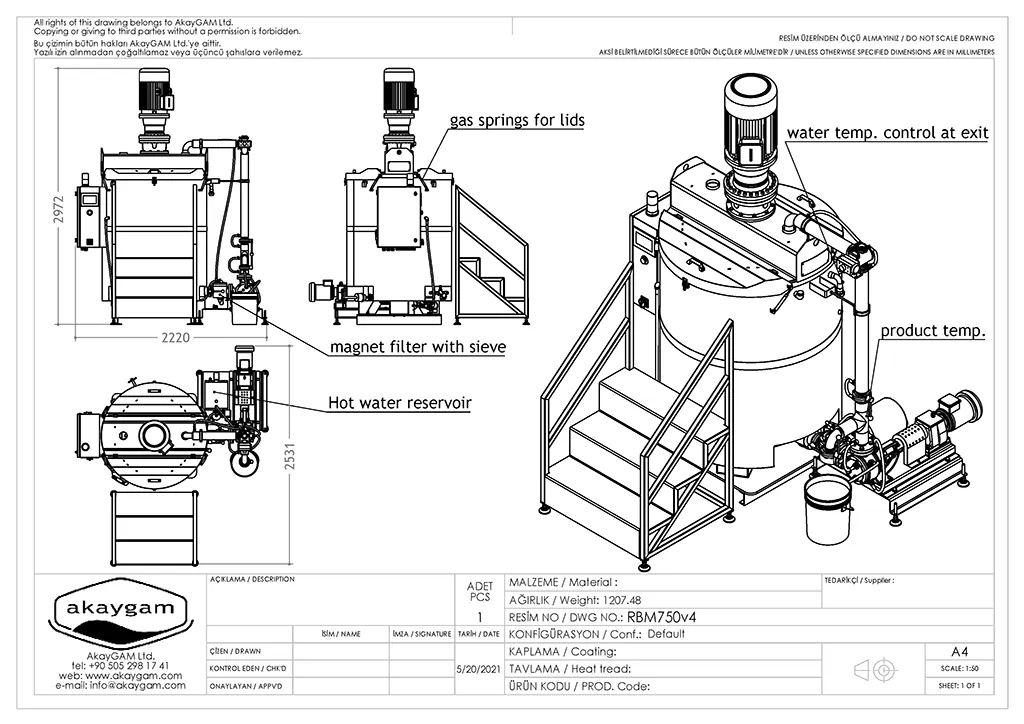

Because grinding generates heat, temperature control is a key part of the process. AkayGAM ball mill refiners use a water-jacketed tank combined with a controlled heating system to maintain a stable refining environment. Depending on the model, cooling is provided by a built-in cooling circuit or by an external cold-water connection. This helps protect flavor quality, avoids overheating, and keeps the chocolate in an ideal working range throughout the batch.

In a typical workflow, ingredients are first mixed in a pre-mixer to dissolve powders and break down lumps before entering the refiner. This improves refining efficiency, shortens processing time, and supports a more consistent final viscosity. Once the batch reaches the desired fineness, the product can either be discharged directly or circulated through a closed-loop system using a pump and a three-way valve for controlled transfer to a holding or storage tank.

Ball mill refining is widely used in chocolate production because it combines compact design with reliable results. It is suitable for applications such as chocolate, praline masses, hazelnut spreads, peanut paste, creams, and tahini, especially when smooth texture and repeatable fineness are essential for product quality.

Auxiliary Equipment

Using cocoa nibs instead of cocoa powder, or refining crushed nuts into smooth pastes, is possible. However, ball mill refiners do not work efficiently with raw materials thicker than 1.5–2 mm. For consistent results, cocoa nibs and nuts should be pre-ground into a thick paste using an impact mill or a beater blade mill.

Because steel ball friction generates heat, models without built-in cooling require an external cold water supply. Tap water or tower water can be used, but we recommend using a chiller for stable temperature control and repeatable refining performance.

Good to Know Before Refining

To get a stable refining process, the chocolate mass should be fluid enough to circulate through the ball charge. Recipes with very low fat content may become too thick and reduce refining efficiency.

If you work with cocoa nibs or roasted nuts, pre-grinding them into a smooth paste can help protect the machine, shorten refining time, and deliver a more uniform final texture.

For consistent production, temperature stability matters. External cooling water can be used, but a chiller is the best option when ambient conditions change during the day.