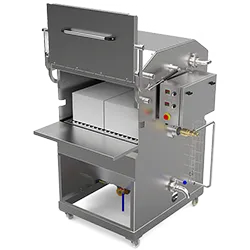

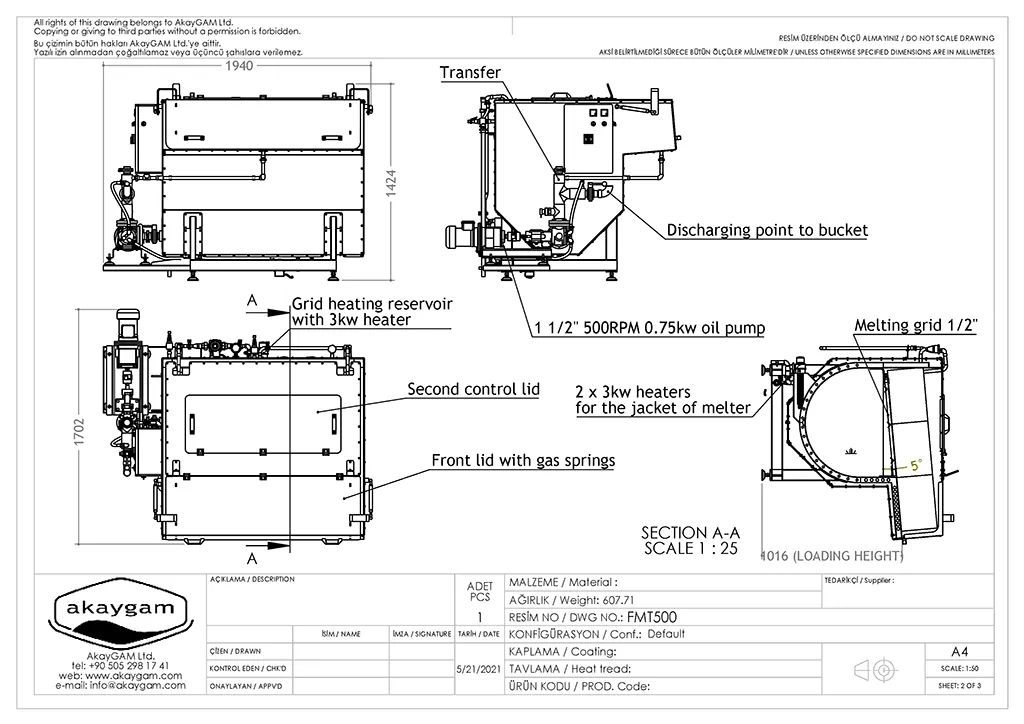

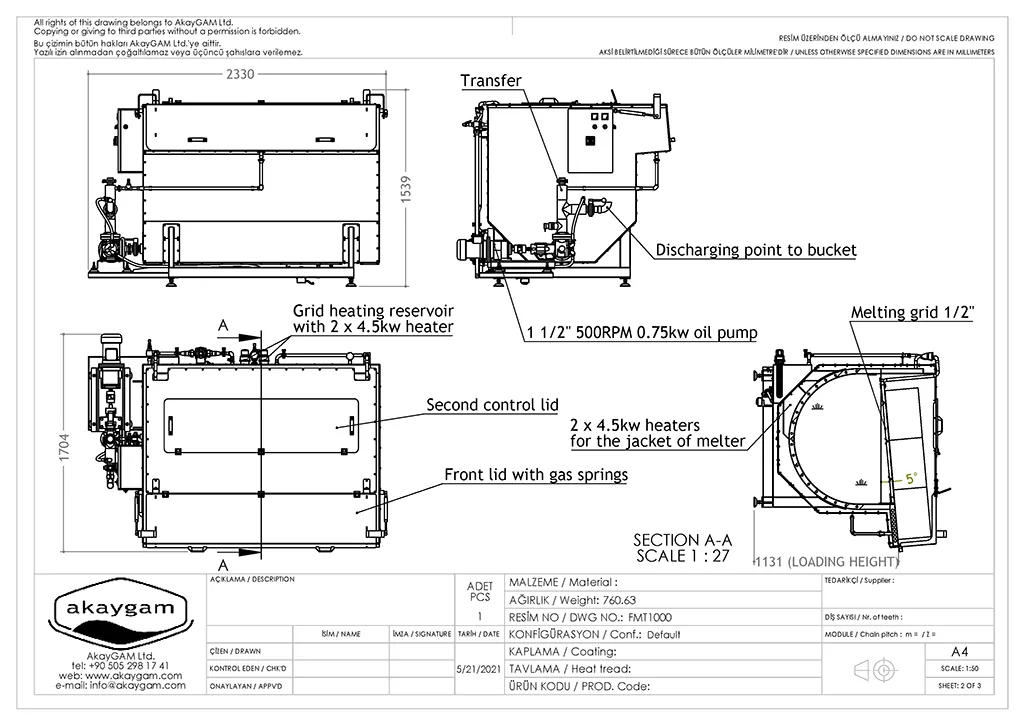

Fat Blocks Melting Machine

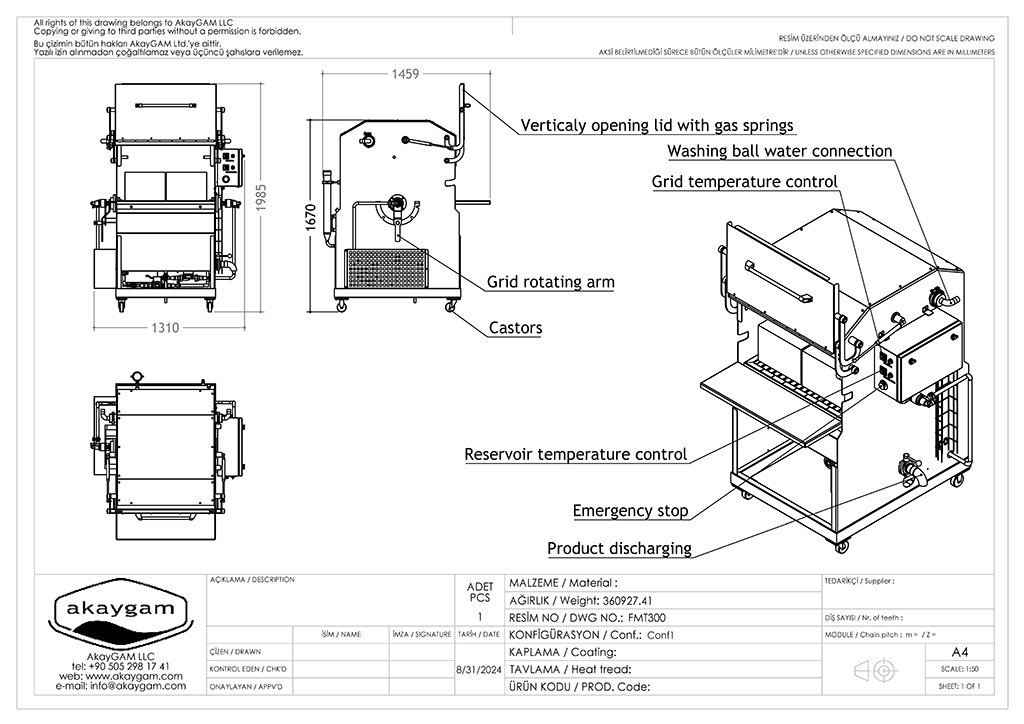

The melting process is speedy due to the grid installed on the equipment. The equipment's height enables convenient hand loading. We make machines with and without a melting grid. If the machine is to be used for melting cocoa butter, a pneumatically operated mixer can be installed. A flowmeter or load cells can be installed to ensure precise oil delivery.

FMT300 VIDEO LINKTypes of fat melting tanks

We produce professional melting machines with glass wool insulation and casters for small workshops and medium-sized confectionery manufacturers.

Share

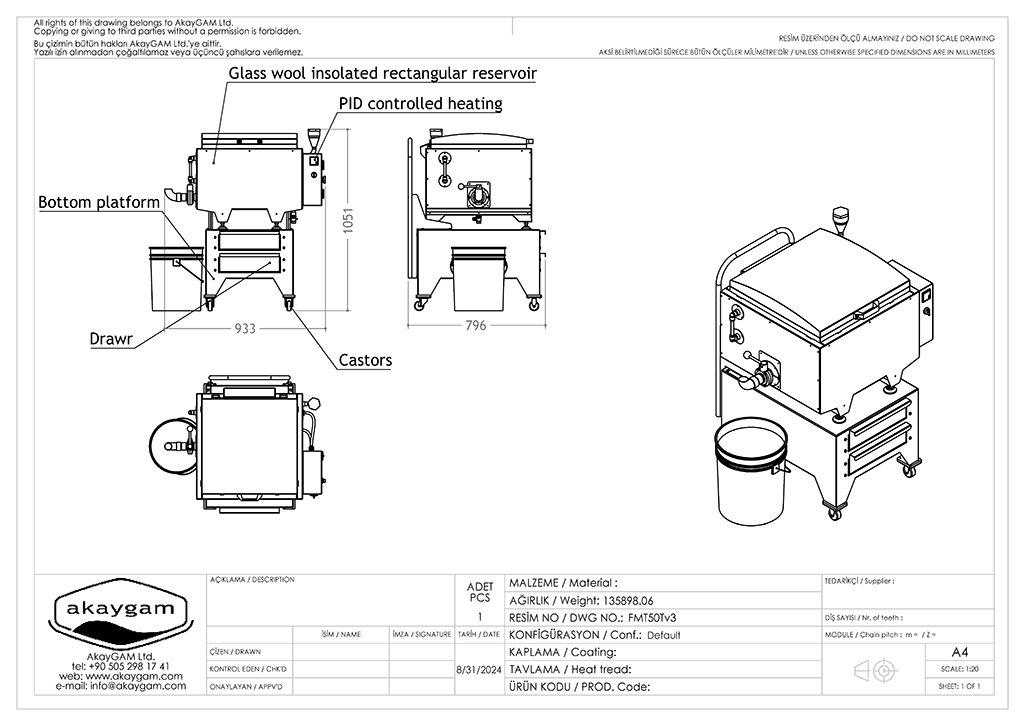

Technical features of FMT50T

FMT50T VIDEO LINKTechnical features of FMT300

FMT300 VIDEO LINKDescription for the rapid fat melters

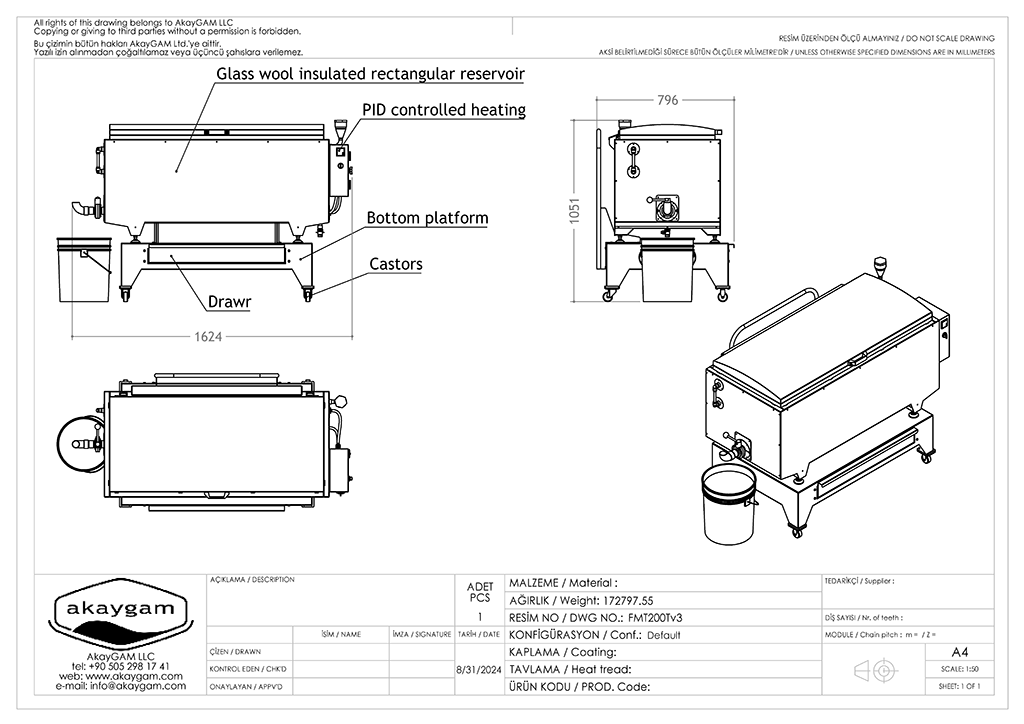

The fat-melting tanks we produce are rectangular to provide maximum melting area. Melters are equipped with glass wool insulation to enhance safety and energy efficiency. They are with PID-controlled heating elements. We mount a grid with separate hot water circulation to achieve a faster melting process (this feature is not valid for fat melting machines with ID FMT50T, FMT100T, and FMT200T). Another important thing we pay attention to in our designs of melting machines is the loading height. Loading of fat blocks should be with minimum effort. The melters we produce are on casters, which makes positioning and relocation operations easier.