Chocolate Lentils Forming Machine

The roller depositor is used to create button-shaped chocolates, which are then covered with sugar syrup. A chiller circulates cold glycol through the forming rollers. The rollers have cavities on their surface, which shape the chocolate lentils.

VIDEO ITypes of chocolate dragee forming machine

Glycol-cooled forming drums for button-shaped chocolate manufacturing. We can add one, two or three pairs of forming rollers on the frame. Forming drums can be 400 mm. or 600 mm. long. All these variants are to achieve different production capacities.

Share

Description for chocolate lentils forming line

The liquid chocolate mass is poured between the cooled forming drums of the machine. Chocolate is formed due to the cavities on the surface of the drums. The chocolate mass passing between the drums obtains the shape but it is in the form of net, the solid product is conveyed to the web removing device, where the crusts are cracked and the button-shaped chocolate form is smoothened. The web removing drum is with an evaporator and a condenser that keep the interior of the device cool.

Auxiliary equipment

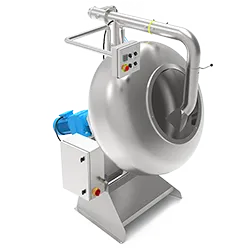

Chiller is required for cooling the forming drums of the chocolate machine. Storage tank is equipment to hold chocolate in homogeneous and liquid condition, it is used to feed the chocolate lentils forming line. Coating pans are required for coating the chocolate dragees with sugar syrup. Coating operations should be performed in a cool and dehumidified room.