One-shot Chocolate Depositor

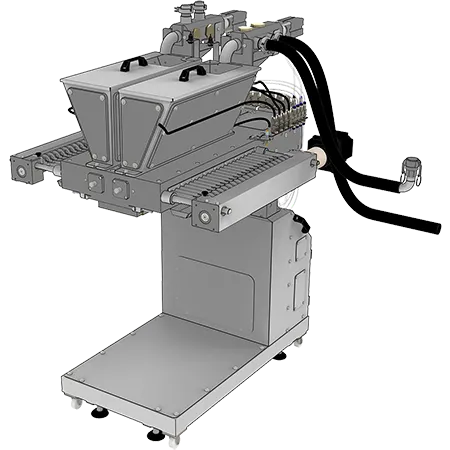

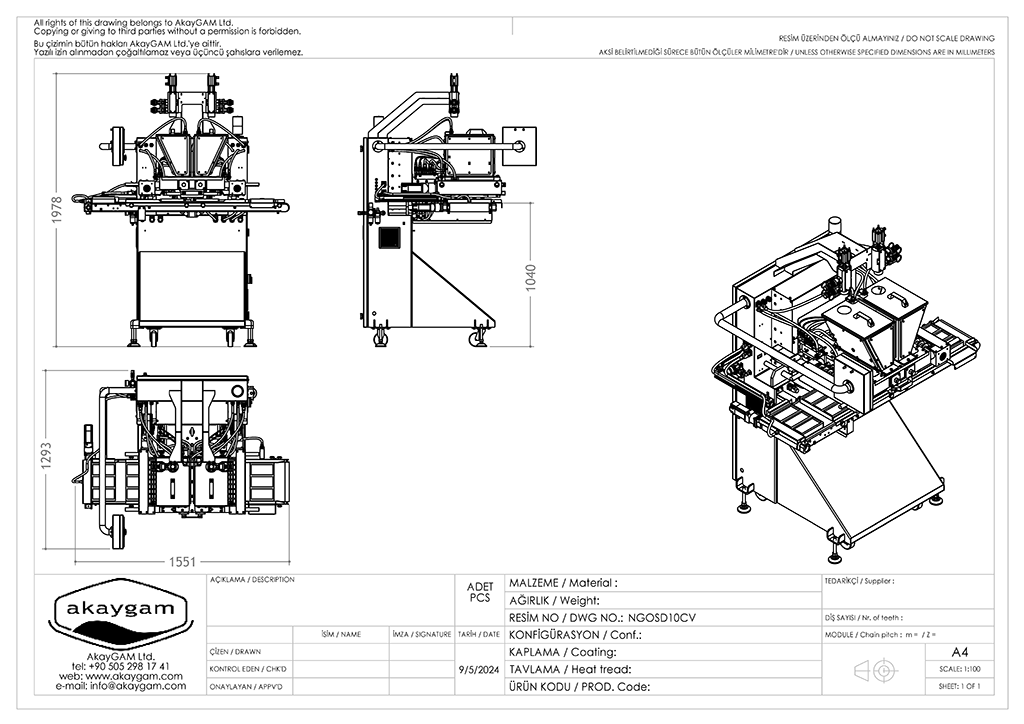

Compound or real chocolate filling machine. Depositor body assembled on C frame. Machine is with servo-driven vertical motion. Accurate PID-controlled dry heating. The suction and pouring valve mechanism can be common or separate.

VIDEO ITypes of chocolate depositors

We produce chocolate depositors for small workshops and medium-sized chocolate manufacturers. Filling machines are standalone with their own frame body. Capable of pouring into molds or onto the belt.

Share

Description for chocolate depositor

The NGOSD-CV series is the new generation one-shot depositor with a traditional common valve mechanism for the suction and pouring pistons. Suitable for chocolate molding line or chocolate drop line. The chocolate filling machine is with dry heating and Z-axis motion. Designed for small, medium-sized workshops and high-capacity manufacturers.

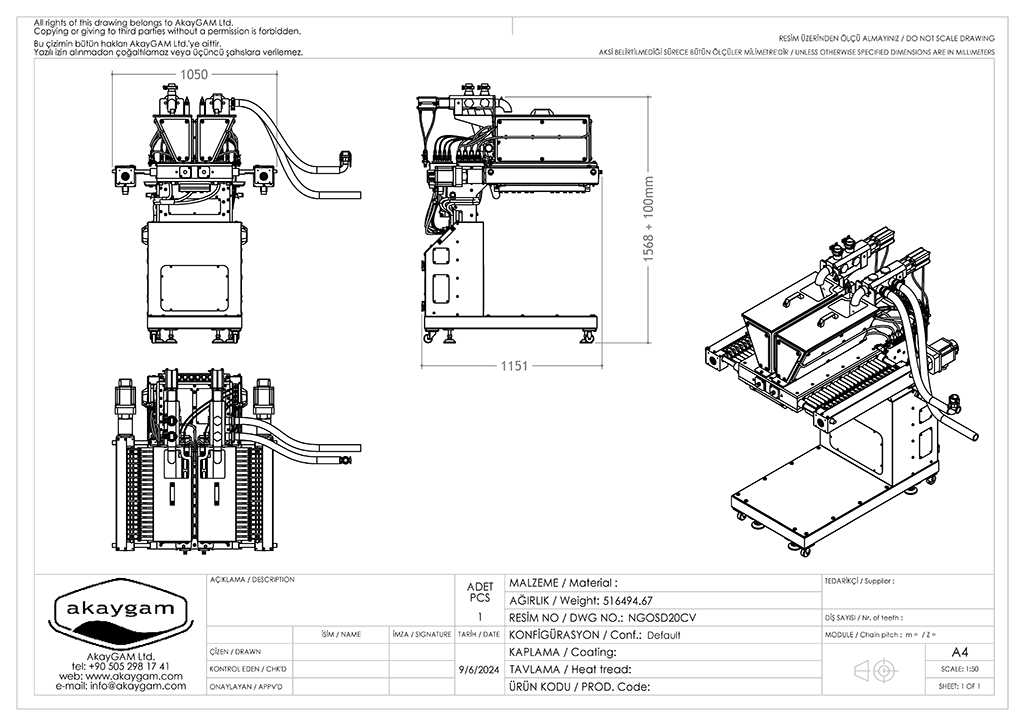

NGOSD-SV series one-shot depositors are with specially designed valve mechanism. Thanks to the separate valve mechanism for each cylinder, weight is more accurate against the CV serie. Thanks to servo-driven pouring and touchscreen any weight can be adjusted easily. Dry heating, Z-axis motion and each cylinder with its own valve are the improvements.

Auxiliary equipment

The storage tank is equipment to hold chocolate in a homogeneous and liquid condition; it is used to feed the tempering machine, which will form the crystal structure of the chocolate.