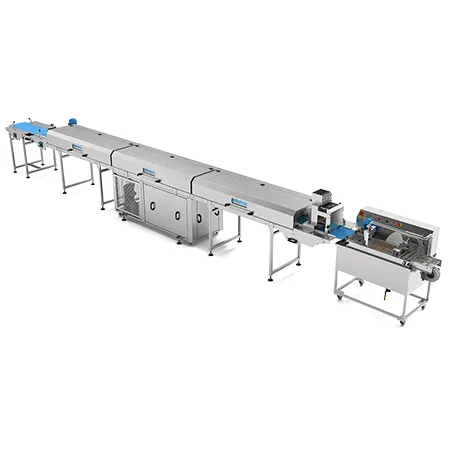

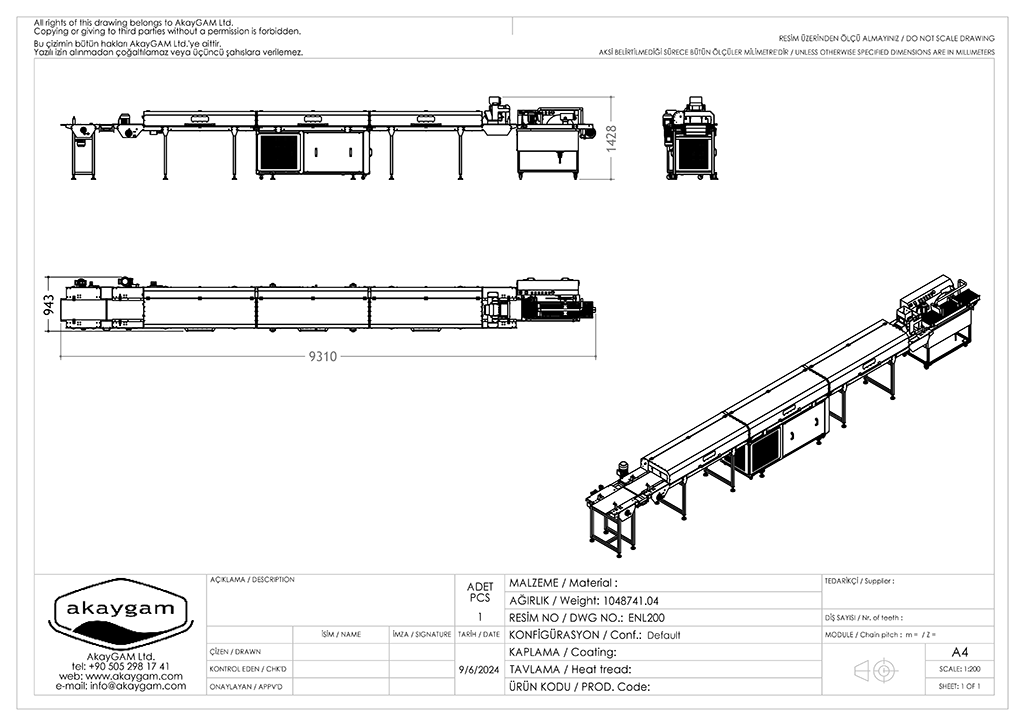

Chocolate Enrobing Line (ENL200)

The line includes a wheel tempering machine, an enrobing belt, a sprinkler and a cooling tunnel. The tunnel of the line is with an automatic belt sliding prevention feature. It is with lighting and the lids are with gas springs. The tunnel is with a built-in condenser. Required cooling temperature can be adjusted on HMI.

Types of enrobing lines

The belt width of the enrober is 200 mm. Cooling length can be up to 10 mt.

Share

Description for chocolate enrobing line

Cover your products with chocolate. Thanks to the sprinkler assembled over the conveyor, you can add texture and increase the visuality by sprinkling food crumbs on the chocolate-covered product. All components of the line are made of stainless steel, aluminum and FDA-approved engineering plastics.

Auxiliary equipment

A ball mill is required for the thinning process of the chocolate ingredients. Storage tank is equipment to hold chocolate in a homogeneous and liquid structure, it is used to feed the tempering machine, which will form the crystal structure of the chocolate.