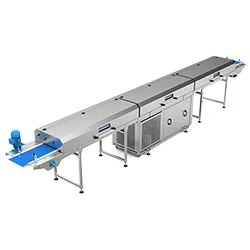

Chocolate Cooling Tunnel

Completely made of AISI 304 grade stainless steel and insulated with CFC-free rubber. Lids of the horizontal tunnels are with gas springs. Lids of the elevator-type tunnel are with safety sensors. Belt sliding prevention feature for the machines with polyurethane belt.

VIDEO ITypes of chocolate cooling tunnels

Elevator type, multi-storey type, multi-storey with polyurethane belt type, tunnel with rod conveyor or with modular belt conveyor or with polyurethane belt conveyor. Designed for molded chocolate cooling or deposited onto belt chocolate cooling.

Share

Description for the chocolate cooling machines

Horizontal cooling tunnels can be produced in different belt widths and lengths to meet the needs of customers. Product conveying may be polyurethane belt, modular belt or rod type. Cooling tunnels with a polyurethane belt are with belt sliding prevention and with a pneumatic belt tightening feature.

Elevator types are suitable for workshops with limited manufacturing space; they are shorter than other types of tunnels. This equipment is a chocolate cooling unit of complex molding lines. Moulded products are moving up and down inside it to obtain the cooling of the chocolate. The length of elevator type is about 80% shorter depending on the horizontal kind.

Multi-story types are shorter than horizontal types, but this does not affect their capacity. These kinds of tunnels are suitable for manufacturers with limited production areas. As product-conveying rails or a polyurethane belt can be used. They also may be used at drops or chips chocolate manufacturing.

Cooling must be accurate because the crystallization process started with temper and will continue until the cooling process is ended. Accurately controlled temperature will redouble the quality of the chocolate. We use mist eliminators to deliver dry air onto the product.