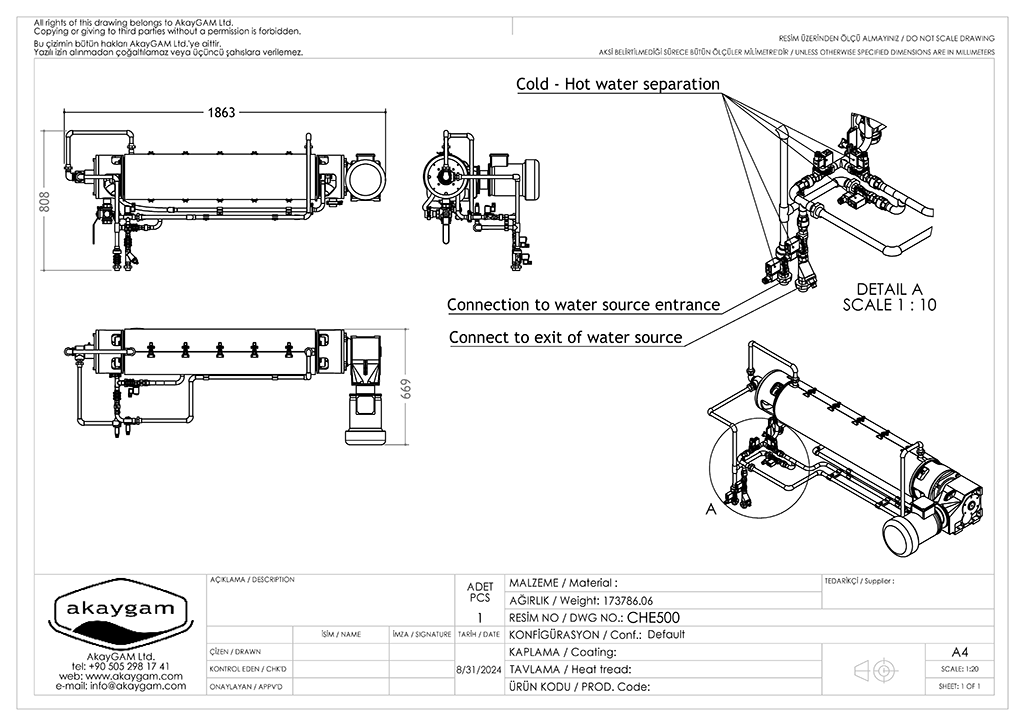

Heat Exchanger For Tempered Chocolate

Prevents thermal fluctuations within the storage tank that may arise as a result of bypassing tempered chocolate back into the storage tank.

Types of chocolate heat exchangers

We produce chocolate decrystallization tubes (continuous reheating devices) for small workshops and medium-sized confectionery manufacturers.

Share

Description for chocolate decrystallization

The chocolate transfer pipeline from the tempering machine to the forming units must be bypassed to the storage tank. This ensures that chocolate is continuously circulated and that the solid ingredients are not separated from the fat. But the direct bypassing of tempered chocolate to the storage tank will change the storing temperature. Tempered chocolate must be reheated to approx. +45°C (equal to chocolate temperature inside the holding tank).

Break the crystal structure of tempered chocolate and feed it back to the storage tank.

Related equipment

The output of the decrystallization tube should be transferred to a holding tank. In case the heat exchanger is going to be used for cooling purposes, then a chiller is required. A heat exchanger can be used as a cooling device for a caramel cooking plant.