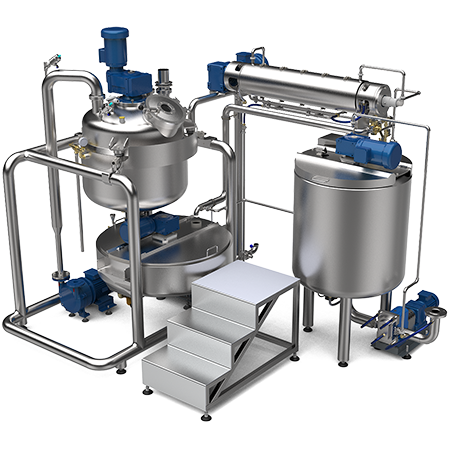

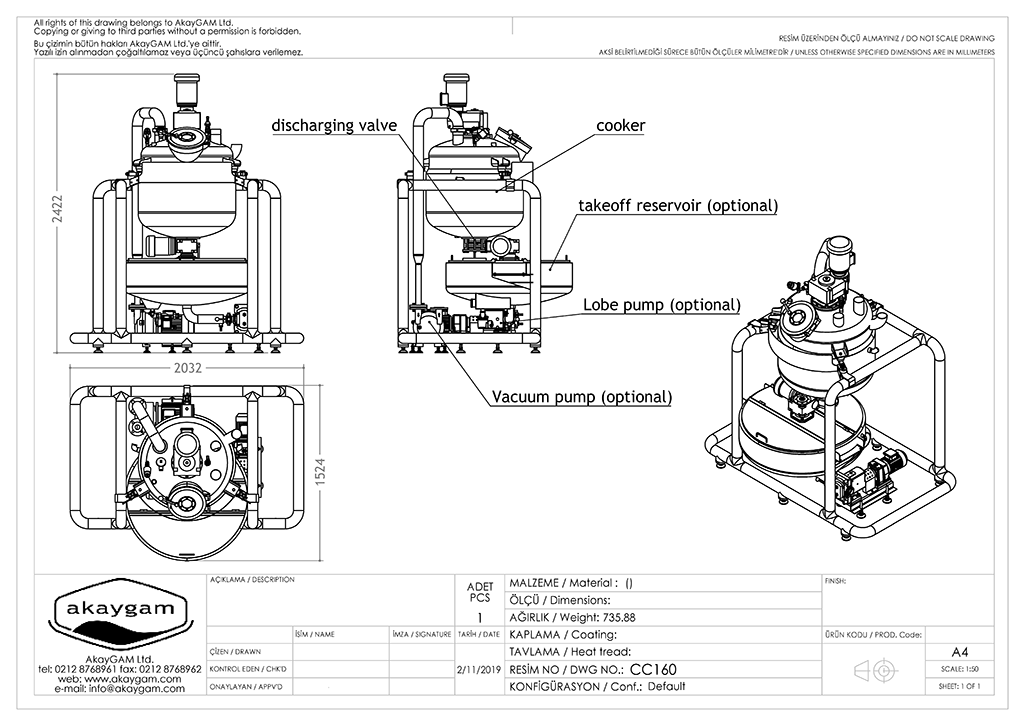

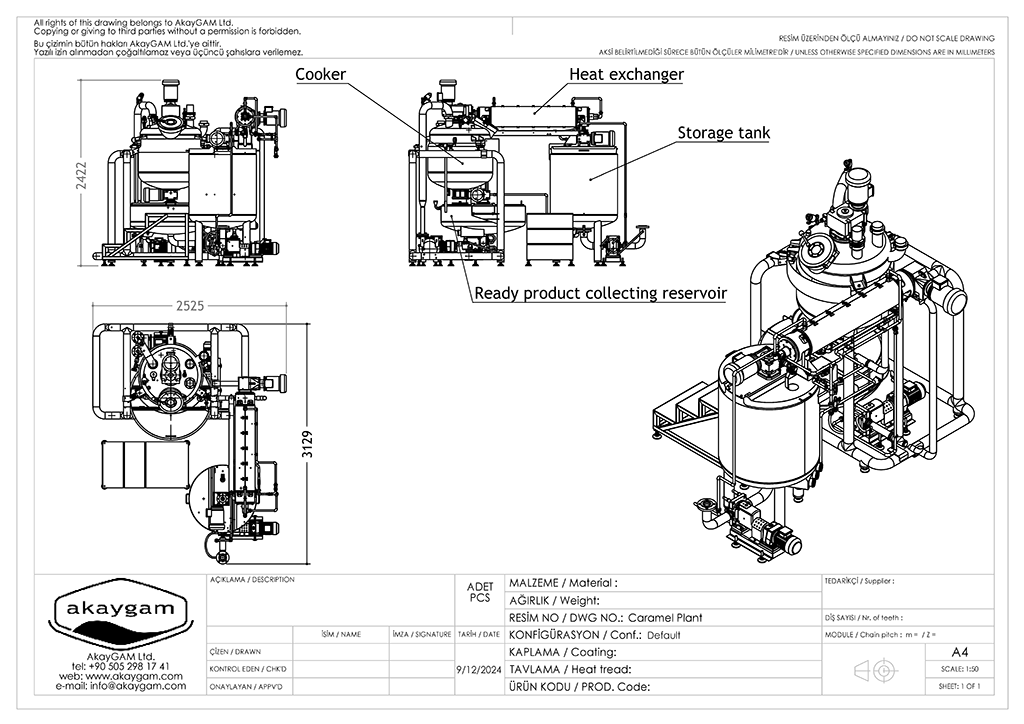

Caramel Cooking Plant

Description for the caramel cookers

The main component of the caramel or toffee candy manufacturing plant is the cooker. The reservoir has a hemispherical shape. Agitation speed is adjustable, and the mixing arms are equipped with Teflon scrapers. The system is HMI and PLC controlled. A water-jacketed take-off reservoir with agitation, a helix-rotor heat exchanger, a vacuum pump, and a storage tank complete the plant.

Auxiliary equipment

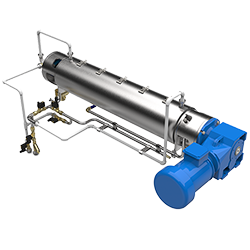

The chiller supplies cold water to the heat exchanger, which is used for cooling the freshly cooked caramel while transferring it to the storage tank. A heat exchanger is required to be able to use caramel immediately in the forming or filling line; otherwise, caramel will be cooled naturally at the resting tank.