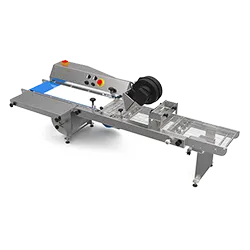

Compact Chocolate Molding Line

This compact chocolate forming line is designed to make either filled or plain chocolates. The filling machine of these lines uses a one-shot outpouring method, which allows both the filling and the outside casing to be poured simultaneously.

VIDEO LINKTypes of mini chocolate molding lines

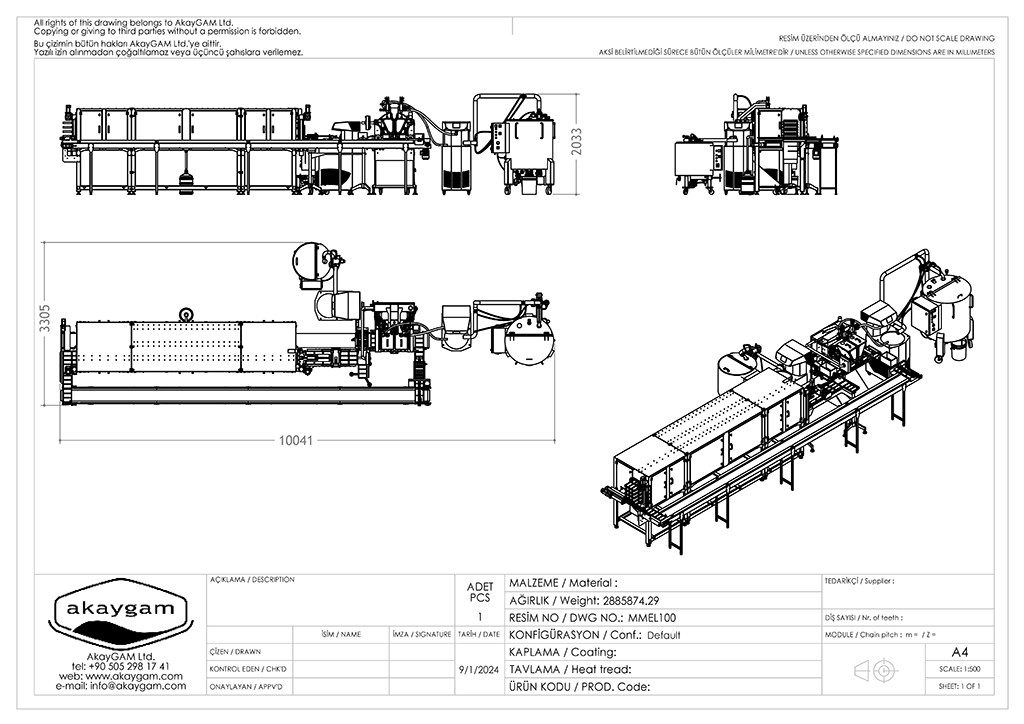

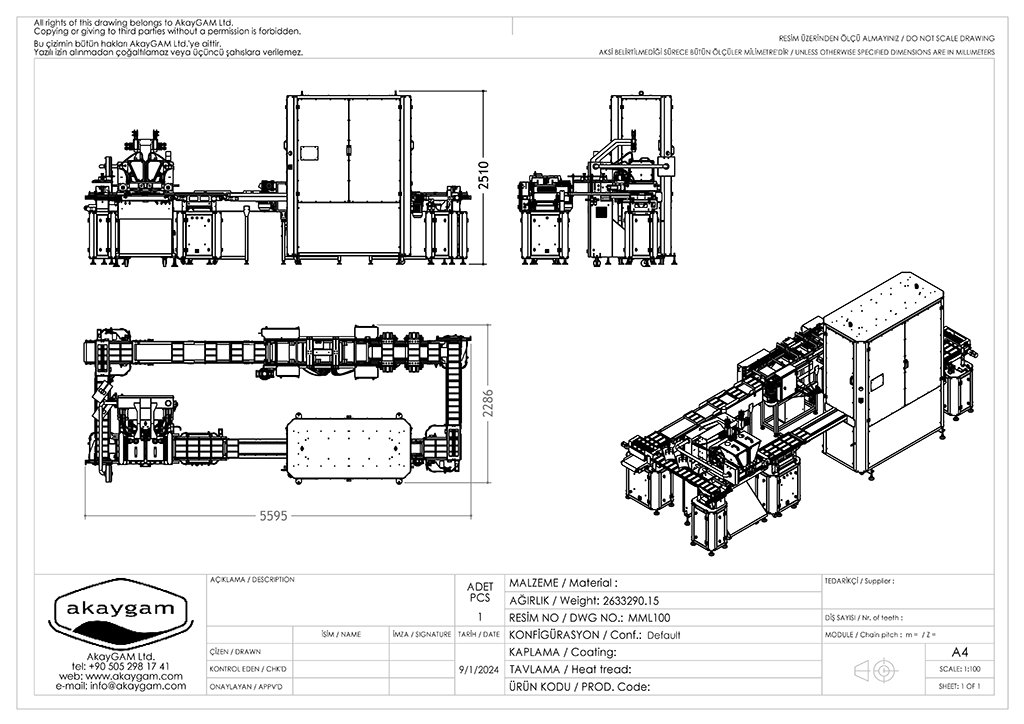

We manufacture combined production lines (MMEL100) and compact lines with demolding capability (MML100) for small and medium-sized confectionery makers.

Share

Description for compact chocolate molding line

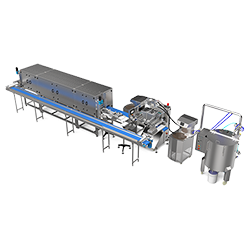

The MMEL series mini line has a production capacity of up to 100 kg/h. The line is developed for artists who have limited space and wish to transition to automated manufacturing. The cooling tunnel is a multi-story structure with a polyurethane belt. The tunnel's integrated conveying feature allows the MMEL production line to produce poured directly onto belt chocolates, molded chocolates, and chocolate-covered products. The cooling tunnel is connected horizontally to the polycarbonate mold flow. The line is designed specially for center-filled (fat-based) molded chocolate manufacturing, although it can also be used as an enrobing line or to make chocolate sticks or drops with or without center-filling. Different chocolate pouring techniques are installed inside the PLC and can be selected on the HMI screen. As the depositor is a one-shot type, utilizing chocolate with crushed nuts or crunch is prohibited. The sprinkler can be used to feed solid particles before or after the depositor.

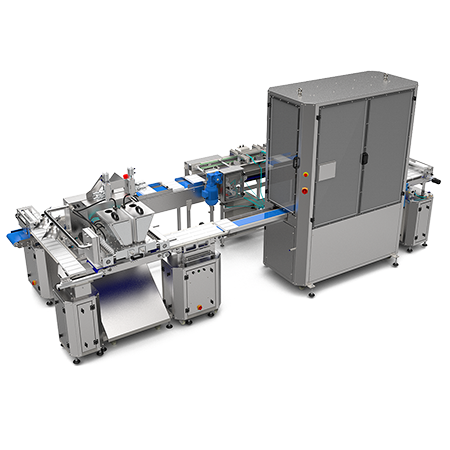

The MML series compact line has a capacity of up to 200 kg/h. Designed for artisans with limited space who want to switch to automated manufacturing. The cooling tunnel is elevator-type and it is the key factor restricting capacity. Line includes a demolding feature. The main goal of this design is to keep the length of the line as short as possible while looping the molds without any user intervention.

Auxiliary equipment

A ball mill is necessary to refine the chocolate ingredients. The storage tank serves to keep chocolate homogeneous and liquid. The tempering machine will form the crystal structure of the chocolate. Enrober can be connected to the MMEL100 molding line.