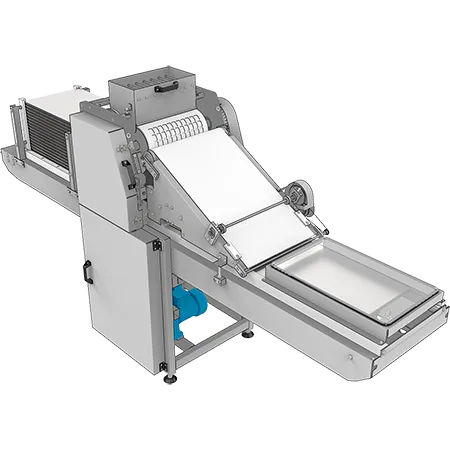

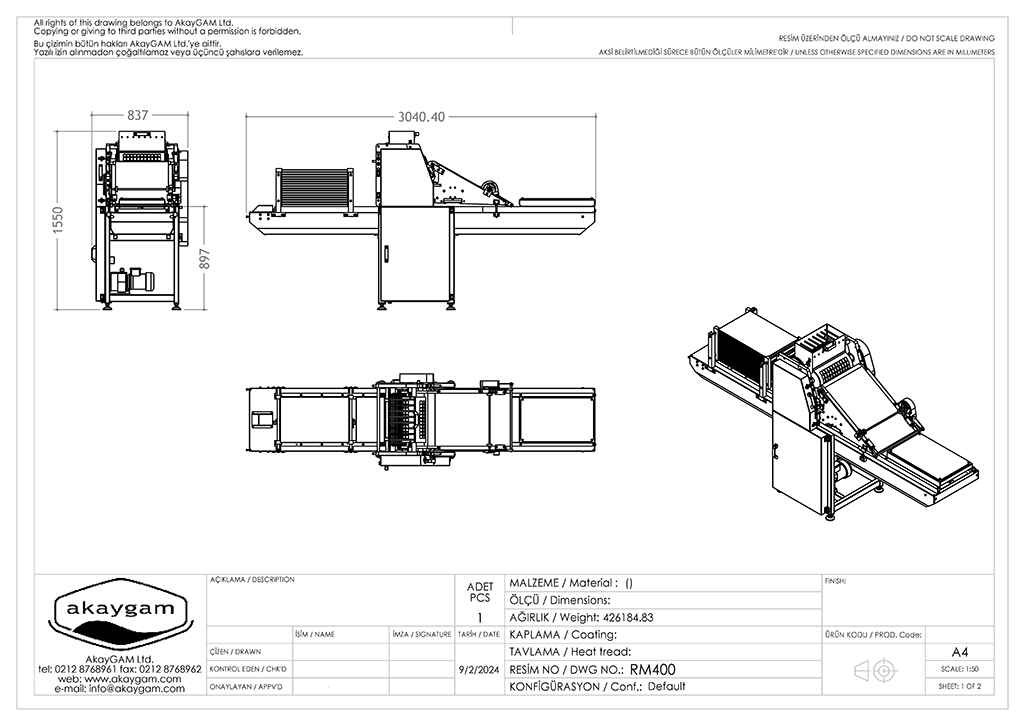

Rotary Moulder (RM400)

Designed to form short dough cookies. The machine extracts the shaped dough onto a cotton canvas and transfers it onto 400 × 600 mm trays.

VIDEO IShort dough cookie forming machine for 400 × 600 mm trays

Designed for standard 400 × 600 mm trays.

Share

Description for the cookie forming machine - rotary moulder

The RM400 rotary moulder is designed to form and extract short dough cookies onto a cotton canvas and then transfer them onto 400 × 600 mm trays. The main components are the forcing roll, moulding roller (forming drum), extraction roll, and scraper. To reduce pressure differences and minimize bridging, the hopper should not be filled completely.

Scraper knife position is critical: if set too high, cavities will not fill correctly and extraction problems may occur; if set too low, cavities may overfill and cookies can be extracted with a tail. Conveyor and forming drum speeds are adjustable via VFDs. For safety, the hopper is fitted with a protective grid. The machine can be equipped with a tray feeder and tray conveyor, and includes a rotating rod to scrape the bottom of formed cookies. Rotary moulding eliminates the need to sheet the dough and avoids cutter scrap that must be recycled.