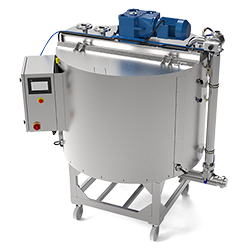

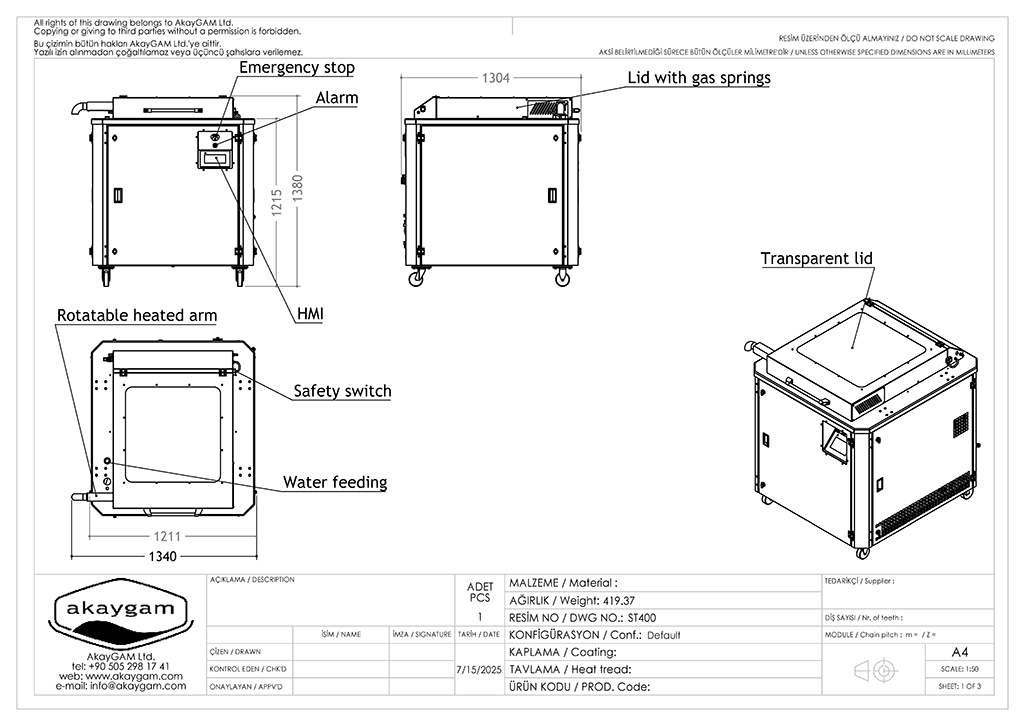

Chocolate Melting Machine

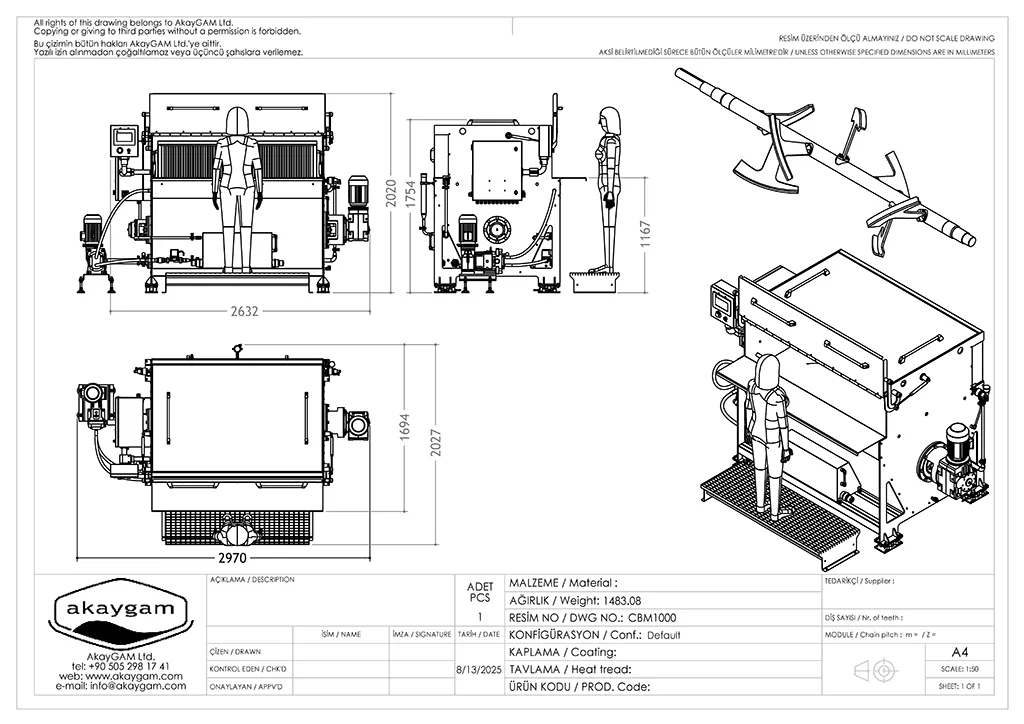

Our chocolate melters are manufactured entirely from AISI 304 grade stainless steel, ensuring durability, hygiene, and compliance with food industry standards. The bottom and side sheets of the tank are designed with increased thickness to withstand continuous operation and heavy loads of chocolate mass. A generously sized water jacket surrounds the tank, maintaining consistent temperature and preventing heat loss during the melting of chocolate buttons or blocks. The CMT1000 model is equipped with bottom and side wall scrapers that ensure uniform mixing and prevent product build-up, while a stainless steel lobe pump combined with a 1500-micron sieve filter guarantees smooth, particle-free chocolate circulation. Heating is provided by autoclave-type heaters, which offer reliable thermal performance and allow replacement without draining the water from the jacket, minimizing downtime and ensuring uninterrupted production.

Types of chocolate melting tanks

Beside machines for laboratory use, we also produce professional cylindrical or rectangular chocolate melters with casters or load cells for small workshops and medium-sized confectionery manufacturers.

Share

Description for chocolate melting machine

The chocolate melters CMT1000 and CBM1000 are glass wool insulated. Melters can be cylindrical or rectangular with PID-controlled heating elements. Agitation is speed adjustable and it can operate continuously or intermittently. Water inside the twin-shell coat ensures heating and keeps the temperature of chocolate mass constant. Chocolate melting machines are used to melt chocolate drops or chocolate blocks and to store it in a constant temperature and homogeneous structure.

Melt your couverture drops or blocks in water-jacketed reservoirs constructed entirely of AISI 304 grade stainless steel. The chocolate melters can also serve as storage tanks.

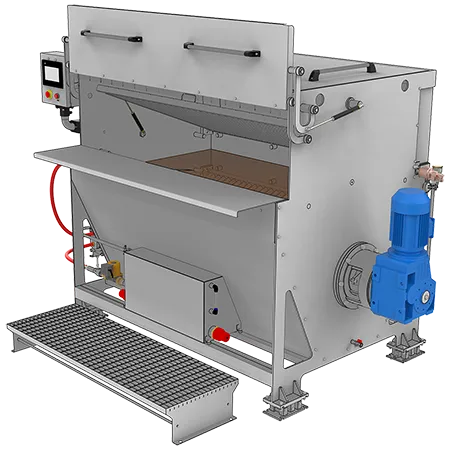

Related equipment

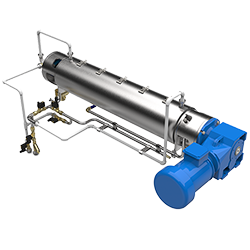

Chocolate inside the melter can be transferred to the storage tank so the device is ready for the next melting batch. If the equipment will also be used for resting, preventing thermal fluctuations that may occur because of bypassing tempered chocolate back to the reservoir is required. Tempered chocolate has to be heated to the temperature of chocolate within the melting tank. Use a decrystallization tube for the chocolate reheating purpose.