Chocolate Covering (Enrobing) Machine

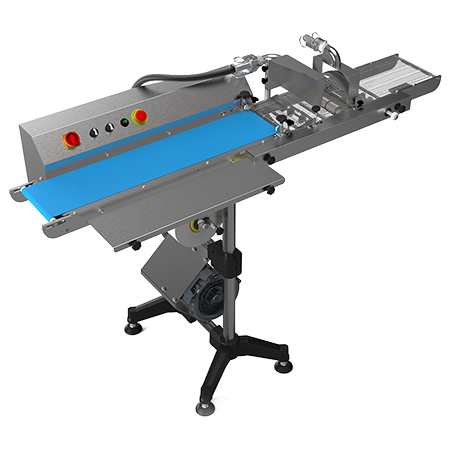

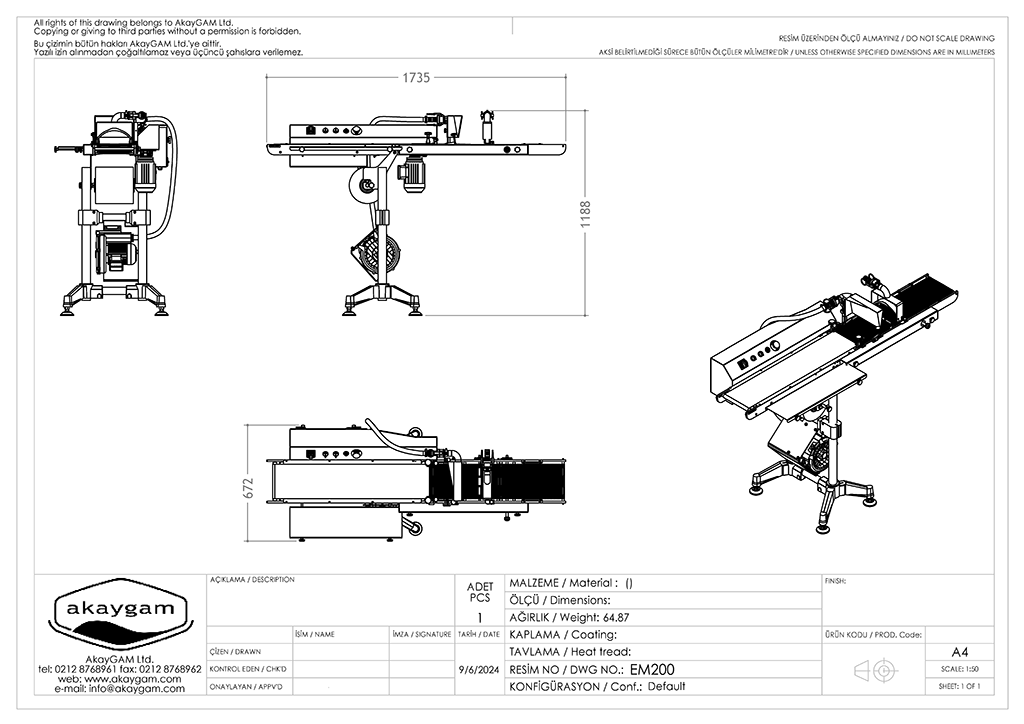

Used to cover various centers with chocolate. Partial or full coating of dried fruits, wafers, cookies and similar products.

VIDEO ITypes of chocolate enrobers

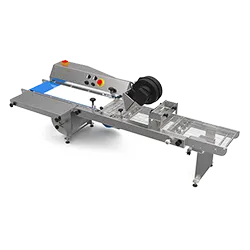

Enrobers for small workshops. We produce models that can be coupled to continuous tempering machines or wheel tempering machines.

Share

Description for the chocolate enrobing belt

Enrobing machines are used to cover different sweets with chocolate. Cover thickness is related to air blowing rate, vibration violence, and the rollers' distance mounted at the bottom of the wire mesh. The sweets entering the enrober are transferred from a plastic feed belt onto a wire mesh belt and pass under a curtain of chocolate; there is a plate or a trough fitted with a roller underneath the mesh to ensure controllable coating of the underside of the sweet. The excess mass from the curtain falls through the wire mesh belt into a sump and is recirculated. Part of the mass is diverted through a de-temperer and is then re-tempered. Blending of the freshly tempered and recirculated streams controls the overall level of temper in the enrober. After the curtain, excess chocolate is forced off the product by an air blower, and a licking roll is used to control the amount of mass left on the underside of the sweet. There is a vibrator after the blower to remove excess chocolate and to improve the appearance of the sweet; finally, there is a detailing rod between the end of the wire belt and the start of the cooler belt, which ensures tail cutting.