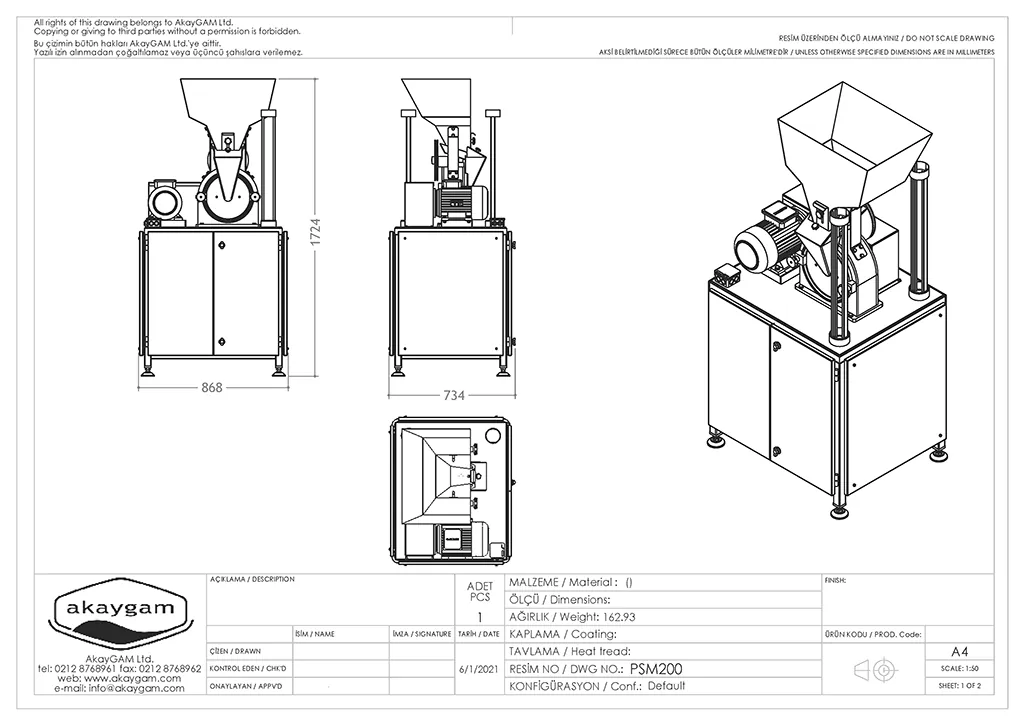

Powdered Sugar Grinder

Using icing sugar in a chocolate recipe will accelerate the grinding process in ball mills. Ball refining is a high-energy-consuming process; by reducing the thinning time, you can achieve power savings.

Types of sugar mills

We produce sugar grinders for small workshops and medium-sized confectionery manufacturers.

Share

Description for the powdered sugar mill

Powdered sugar mill is a pulverizing machine. It is used to mill crystal sugar into fine powder up to 50 microns. Depending on the capacity of the equipment, the rotor can be a hammer or pin-type. Icing sugar is an ingredient of numerous applications, like for chocolate, jams or jellies, ice cream, drinks, or bakery products. The powdered sugar mill can be equipped with a vacuum or screw-type raw material feeder and a screw-type discharging device.