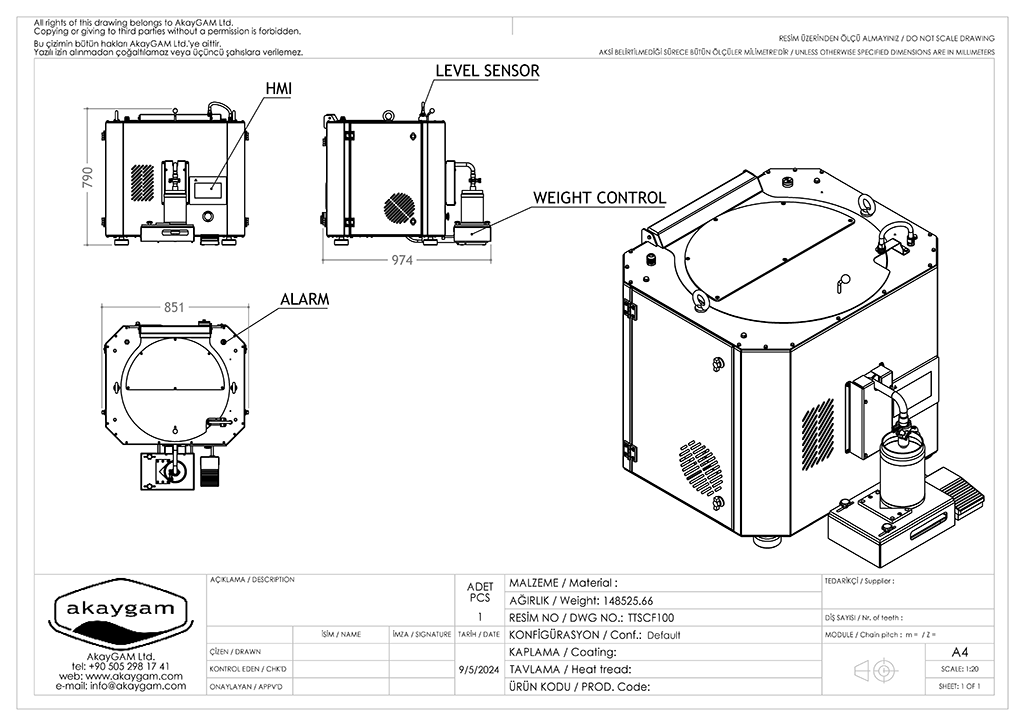

Chocolate Spread Filling Machine

Spread cream reservoir is with mixing and accurate PID heating. Pneumatic or servo-driven pouring feature according to the customer request. In pneumatic devices, the stopper must be manually adjusted in order to change the pouring weight. Machines with servo-motor-driven pumping are equipped with a load cell and weight adjustment can be done easily from the control screen.

VIDEO ITypes of hazelnut spread filling machines

We produce depositors for pouring single or double-colored spreads into jars. On servo-driven models, we use a load cell to control the poured product weight.

Share

Description for the spread cream filling machine

TTSCF100 is a praline paste filling machine with a servo-driven gear pump and a load cell for accurate pouring. Equipment also can be used as a chocolate melting or storage machine.

Auxiliary equipment

The impact mill is used to make thick paste from whole or chopped roasted nuts or cocoa nib. A ball mill is essential for the refining process of the praline spread ingredients. The storage tank is a piece of equipment used to keep spreads homogeneous and liquid, and it is used to feed the spread cream filling machine.