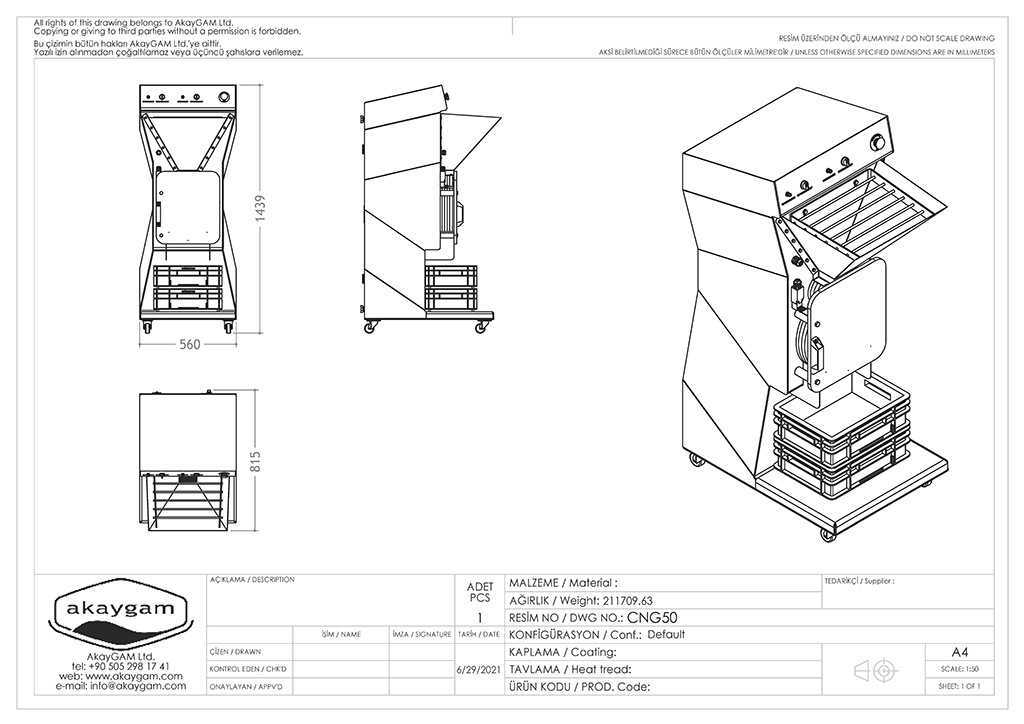

Dried Nuts Grinding Machine

Impact mill to make thick paste from whole/chopped roasted nuts or cocoa nib. The machine is equipped with a top crusher and a bottom grinder.

VIDEO LINKTypes of nib grinding machines

We produce whole nut grinding machines for small workshops and medium-sized confectionery manufacturers.

Share

Description for cocoa nib grinder

It can crush and micronize roasted hazelnuts, peanuts, and cocoa nib into a thick paste as fine as 500 microns. While the upper part of the grinder cracks roasted nuts, having pins in the bottom part of the machine turns the chopped product into a thick paste. The paste then can be thinned in ball mills up to 18 microns.

Pre-grind dried nuts or cocoa nib into a thick paste of up to 500 microns.

Related equipment

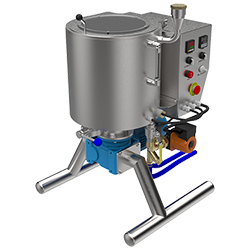

Extra grinding is required to micronize the pre-grinded thick paste. Use a ball mill to achieve the thinning purpose.