Chocolate Tempering Machine

The tempering technique used in wheel tempering machines is the seed method. Machine has a dry heating element with precise temperature adjustment used to melt the chocolate. It is also equipped with cooling fans to absorb the heat of the chocolate; however, to accelerate the cooling process, seeding of unmelted chocolate is required. Melt 80% of the total product in the melting process. Then switch on wheel, set the thermostat to the tempering temperature and Add 20% chocolate drops during tempering process.

VIDEO LINKTypes of chocolate tempering machines

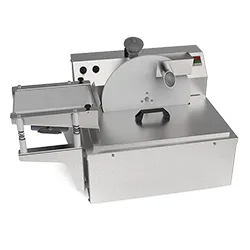

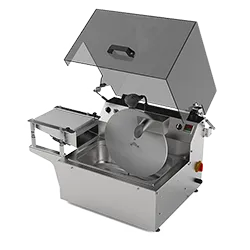

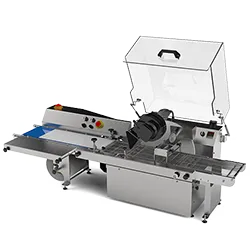

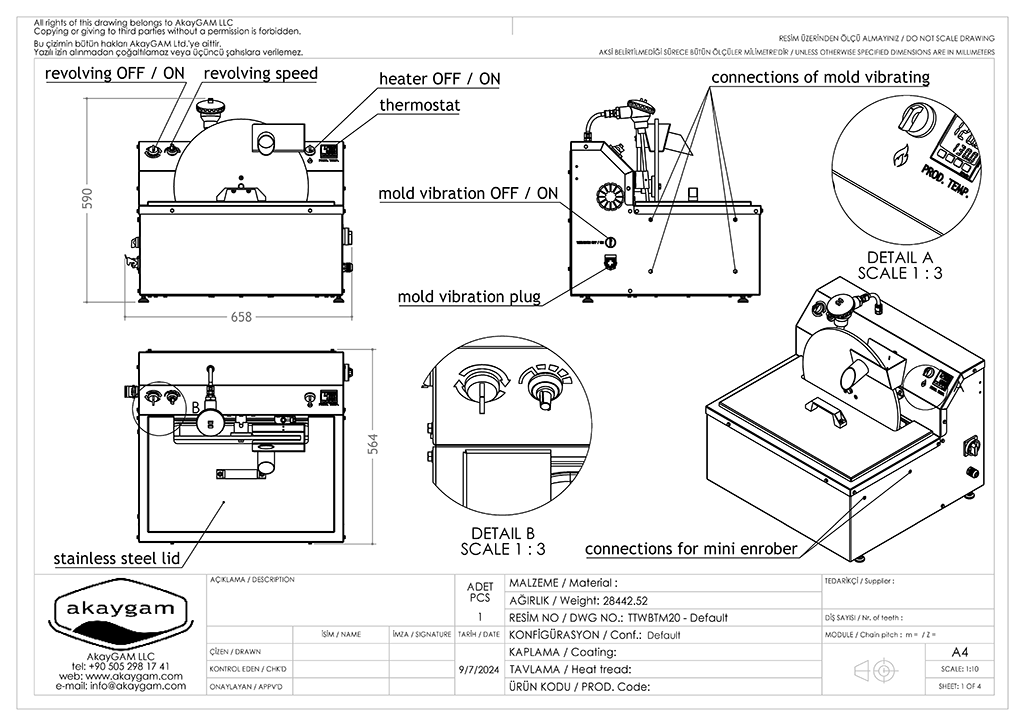

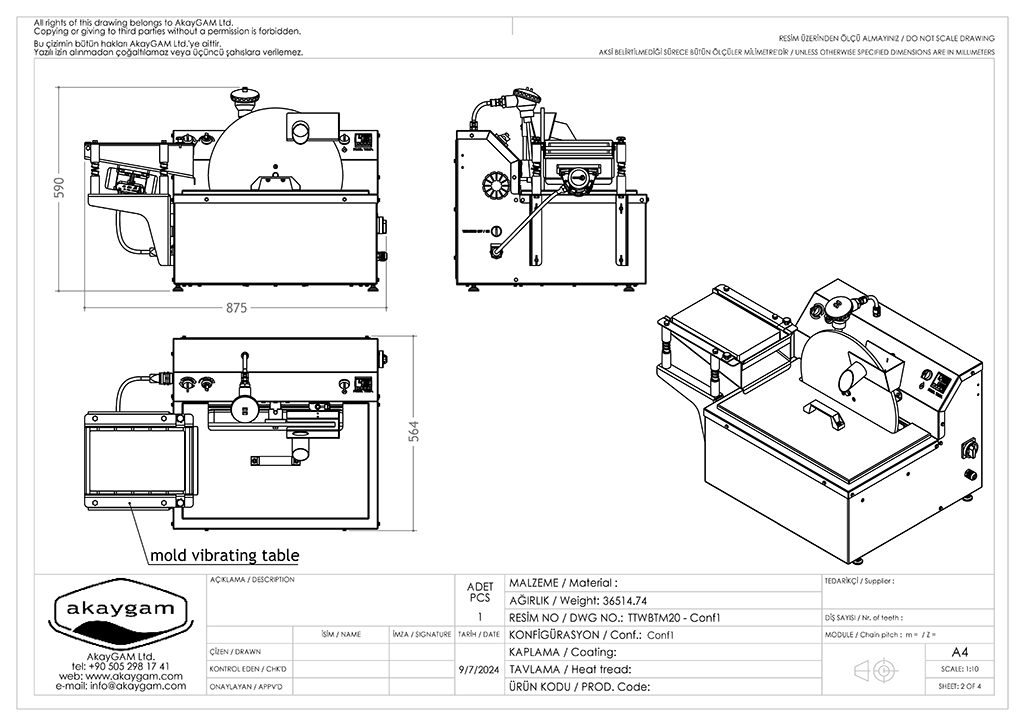

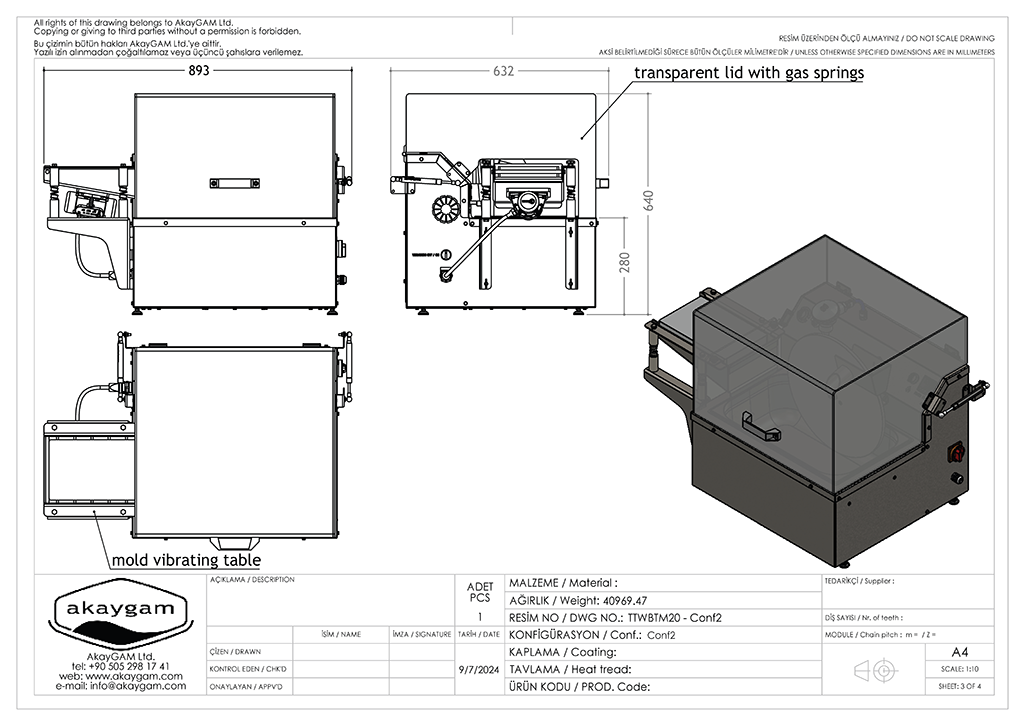

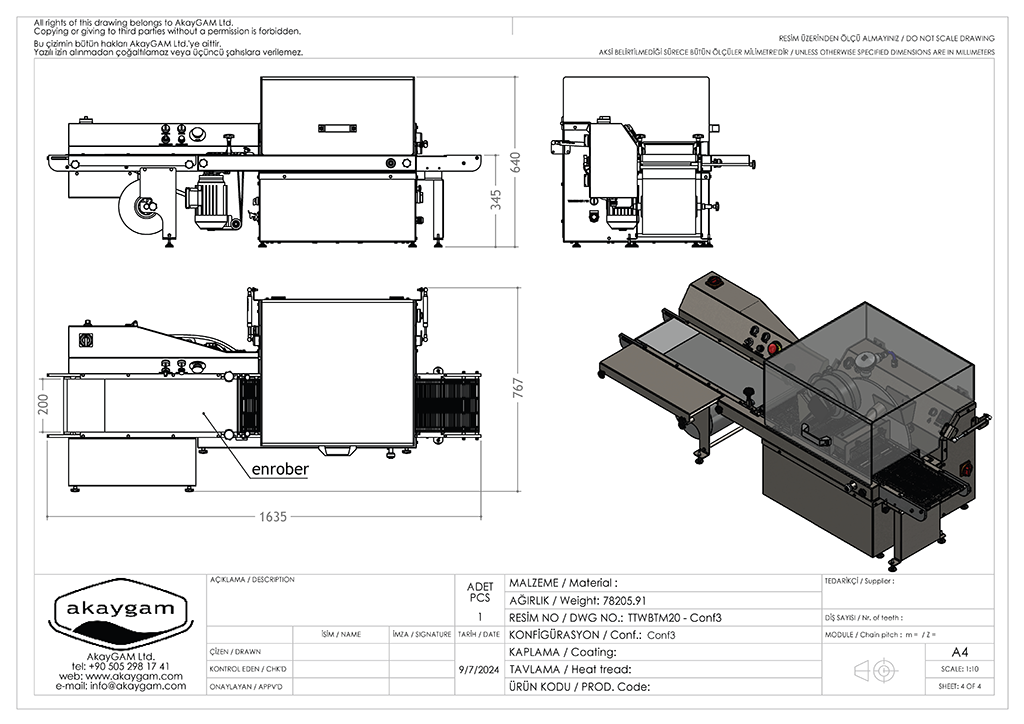

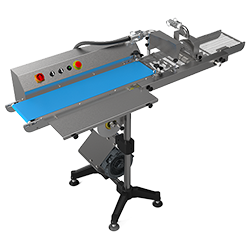

We produce chocolate temperers for small workshops and home use. Mold vibration table, lid with gas springs, and enrobing belt can be assembled to the device.

Share

Description for chocolate tempering machine

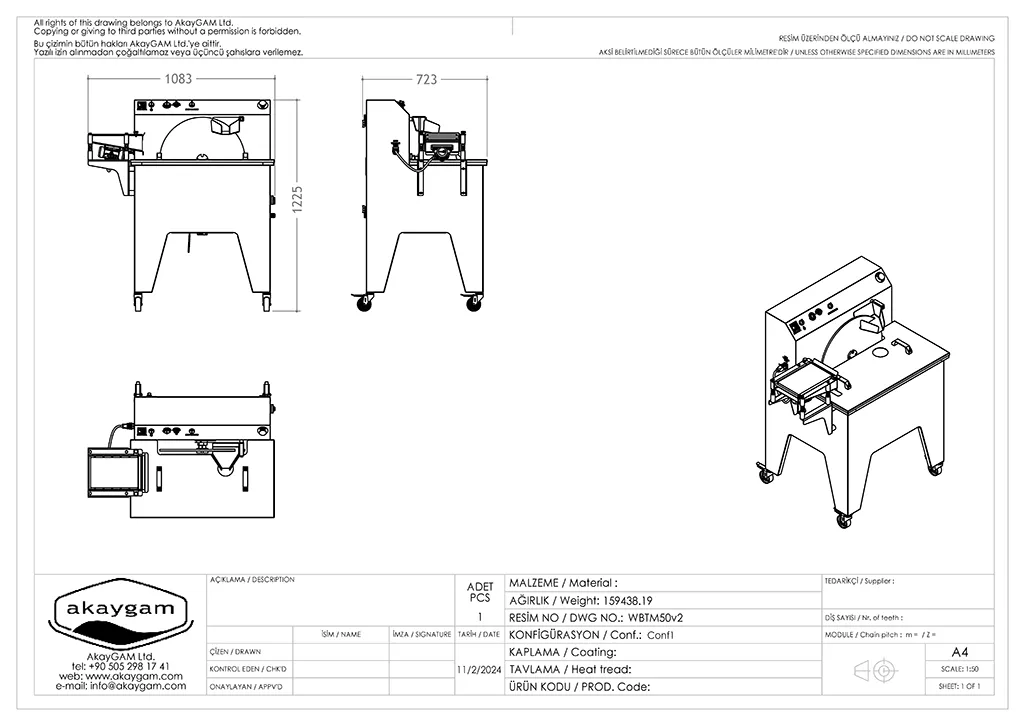

WBTM is ideal for beginners and patisseries, while TTWBTM temperers are table-top types and designed for home use. We produce 20 kg. and 50 kg. reservoir capacity wheel-type chocolate temperers. Designed for those who are looking for an economic tempering solution. The machine is equipped with automatically started and stopped suction fans, which help to remove the heat from the melted chocolate, activating the wheel while tempering operation, and adding some unmelted chocolate will speed up the cooling process. When the product reaches the tempering temperature, the machine will try to hold the temperature constant by automatically switching ON or OFF the heater. To achieve faster cooling, room temperature should be around 20-25°C. With additional devices, the machine can be used as a molding machine or enrober.

Related equipment

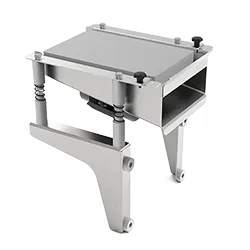

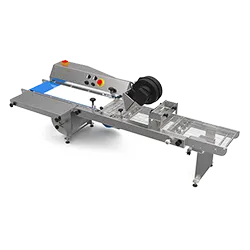

A mold vibrating table is required in case the machine is going to be used for filling polycarbonate molds. Enrober is for covering different sweets in chocolate. It can be assembled to TTWBTM20 and WBTM50.

About the chocolate tempering method

To check if chocolate is tempered, dip a metal spatula or knife blade into chocolate and leave a small film on the blade. If the chocolate is firm and not tacky after five minutes at normal room temperature, it is tempered. If it is still tacky, cool the chocolate about 0.5°C by seeding solid chocolate drops to the reservoir. Repeat the test until the chocolate is tempered.

Improperly tempered chocolate will have the following characteristics.

Properly tempered chocolate will have the following characteristics.