Blend Solid ingredients Into Chocolate

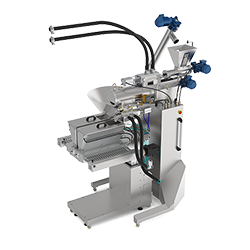

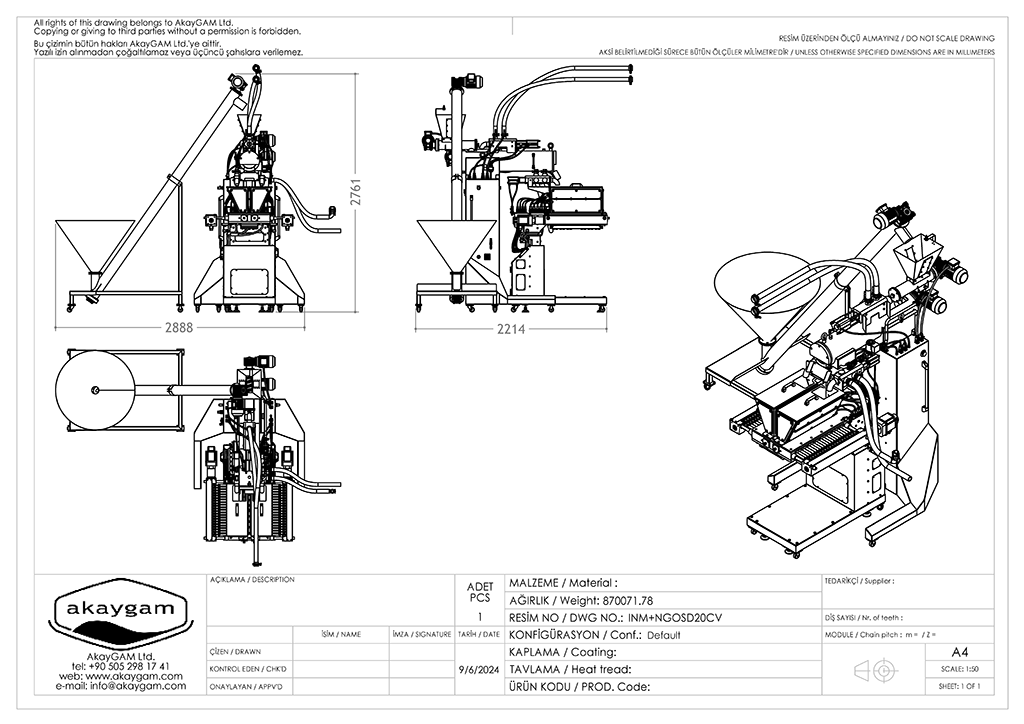

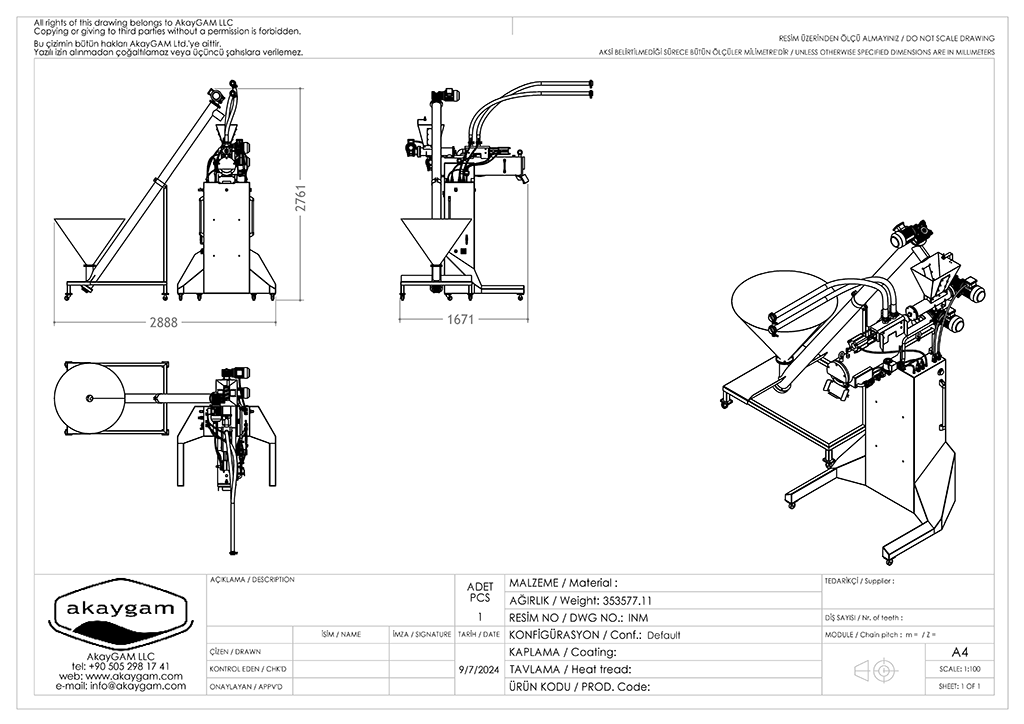

The device can be attached to the back of the chocolate depositor and feed its hopper with chocolate, which is blended with crispy rice, caramel pieces, cookie pieces, chopped nuts, whole nuts or other solid ingredients.

Types of inclusion mixers

We produce continuous liquid and solid particle mixers for small workshops and medium-sized confectionery manufacturers.

Share

Description for the inclusion mixer

Designed to blend solid particles into chocolate, the mixer is fully automated and may begin feeding the depositor's hopper when the product within reaches the minimum level. To avoid breaking the chocolate's crystal structure, all components through which it goes are precisely heated.

Many manufacturers employ a batch method to include the inclusions into the completed product. This can occasionally change the viscosity of the basic product. When the recipe calls for a different inclusion, the mixing reservoir, as well as any transfer piping and equipment, must be cleaned. Use a continuous mixing device to eliminate difficulties with recipe changes.