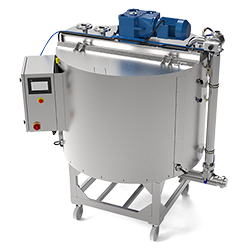

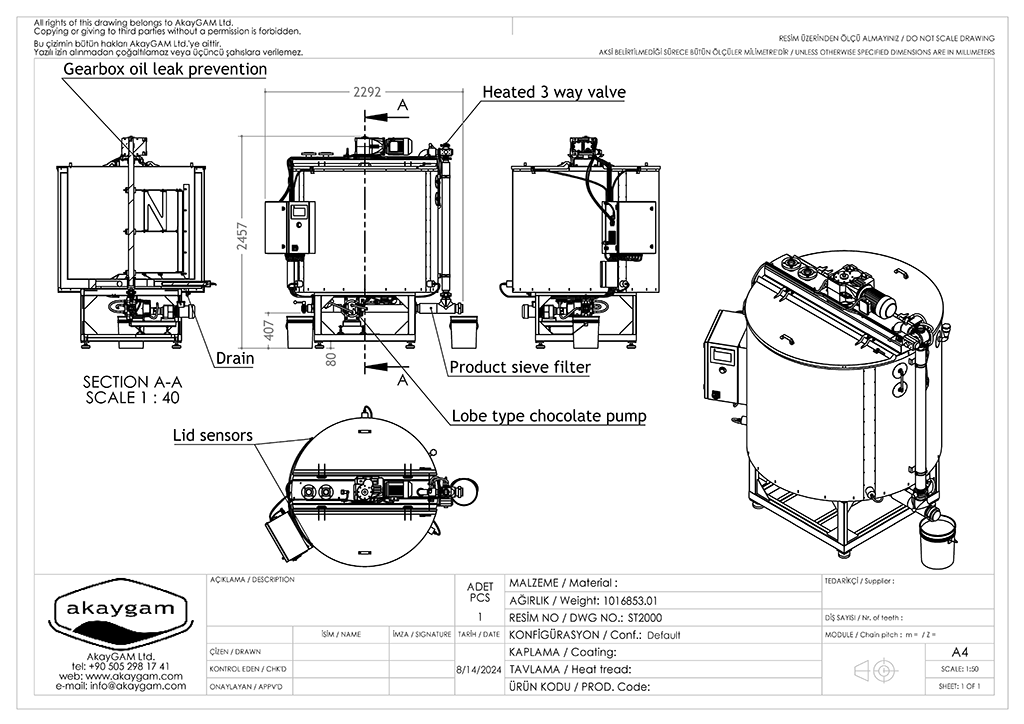

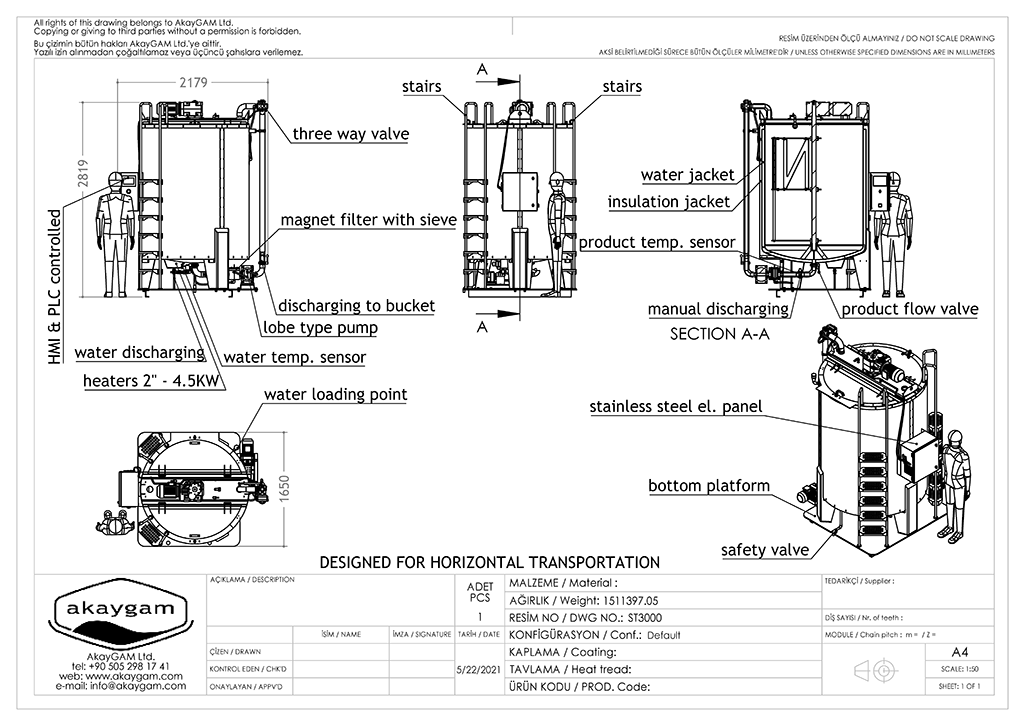

Chocolate Holding Tank

We produce water-jacketed cylindrical chocolate tanks made entirely of AISI 304 grade stainless steel. They are with a PID-controlled heating element. Both mixing principles, continuous and intermittent mixing are available. The rotation speed of the agitation can be adjusted.

VIDEO LINKTypes of resting tanks for chocolate

Beside chocolate holding tanks for laboratory use, we also produce machines for small workshops and medium-sized confectionery manufacturers.

Share

Description for chocolate storage tanks

Resting tanks can be with or without glass wool insulation. The stirrer has adjustable speed and can operate in a continuous or intermittent mixing mode. Water inside a twin-shell coat ensures heating and keeping the temperature of chocolate mass constant. The device is used to store the chocolate at a constant temperature and with a homogeneous structure. Reservoirs with a loading capacity of more than 1000 kg. are not suitable for melting purposes.

Store your chocolate couverture in water-jacketed reservoirs completely made of AISI 304 grade stainless steel and with side wall Teflon or stainless steel scrapers.

Related equipment

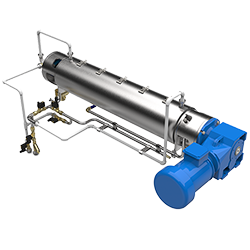

It is necessary to prevent thermal fluctuations that may develop as a result of returning tempered chocolate to the tank. Tempered chocolate has to be heated to the temperature of the reservoir. Use a decrystallization tube for the reheating purpose. Chocolate holding tanks with a capacity greater than 1000 kg. are not suitable for melting. If you need to melt chocolate drops, chips, or blocks, utilize a chocolate melting tank.