Center-Filled Biscuit Dough Extruder

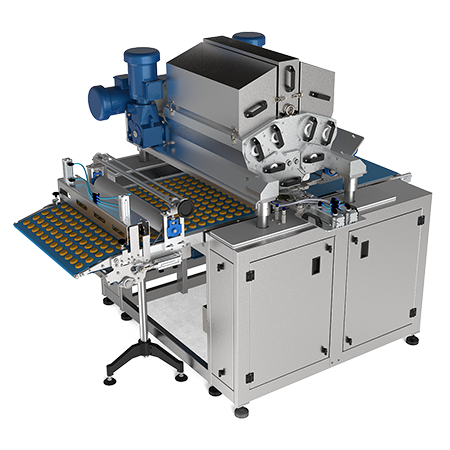

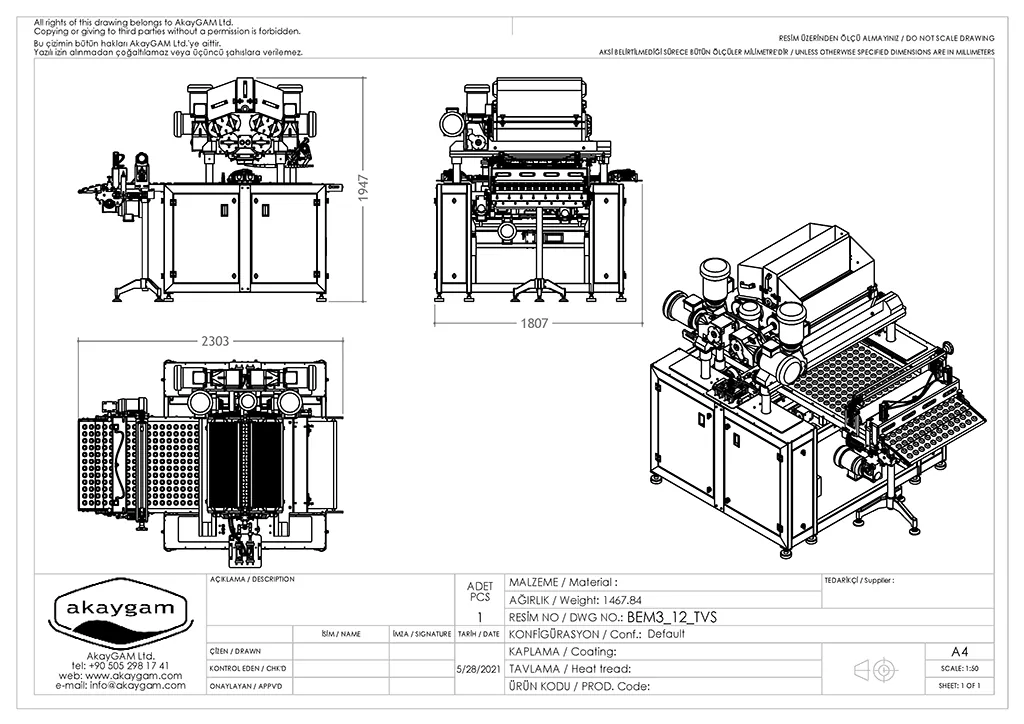

The basic concept of the depositor is to combine two different colored biscuit doughs with cream filling. Wire cutting, guillotine cutting and diaphragm cutting are dough-forming devices that can be assembled to the machinery.

VIDEO ITypes of extruders for center-filled cookies

We produce co-encrusting machines for small workshops and medium-sized confectionery manufacturers.

Share

Description for the cream-filled cookies extrusion

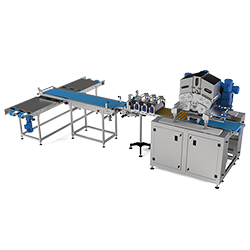

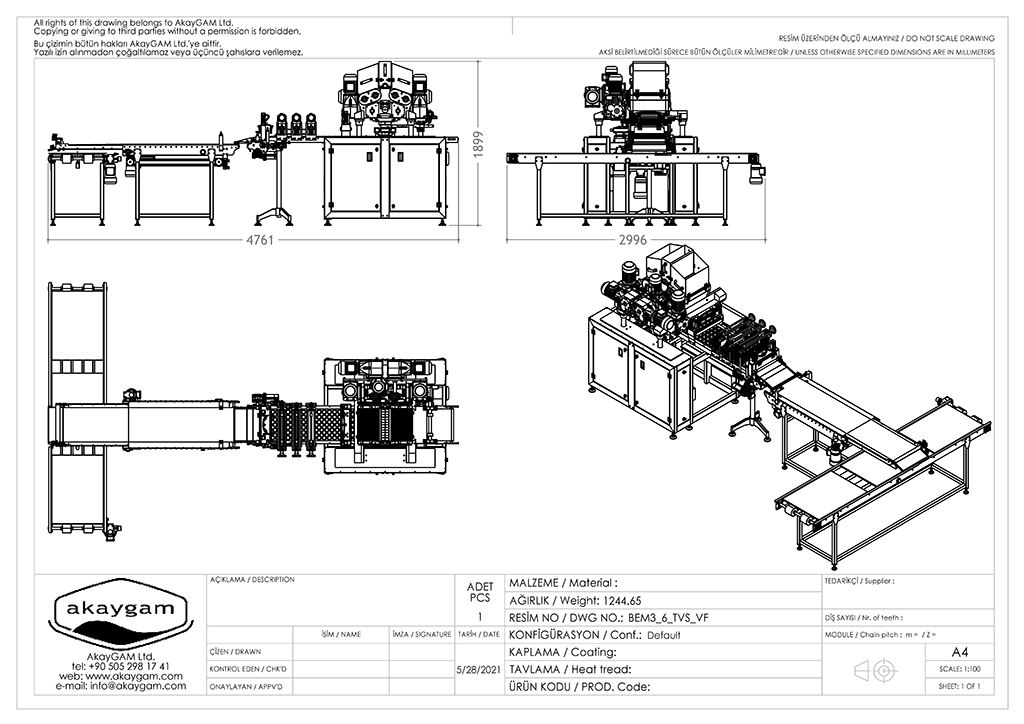

The machine is specially designed for the manufacturing of cookies with micronized liquid filling inside. Double-colored wire-cut cookies and guillotine-cut bar-type center-filled cookies can also be produced. VF series machines are equipped with a reciprocating shuttle conveyor. Fed trays are vertically conveyed to the product flow. The combination of a depositor, retractable conveyor and tray conveyor is suitable for semi-automatic production, as for baking rotary-type oven is used. Thanks to the transverse feature, optimized row distance achieves higher capacity. In case the oven tunnel is used for baking, we recommend the belt to be sheet metal or CB5 articulated wire mesh; other types of belts may break the dough shell and may cause a leak of center-filling. The machine has a vertical head adjustment, which allows variable conveyor-to-nozzle distance. For different dough cutting styles, nozzle-to-conveyor distance should be adjusted.