About Our Company

Founded in 2002, AkayGAM LLC is headquartered in Istanbul, Turkey. With a team of 20 skilled specialists, CAD-supported manufacturing, and a 1,200 m² production facility, we design and manufacture chocolate machinery as well as biscuit and cake production lines for clients worldwide. We specialize in developing preparation, forming, and filling machines tailored to the needs of the confectionery industry.

We utilize high-quality materials and the latest technologies to build equipment that is durable, reliable, and resistant to demanding production conditions.

This content is blocked.

Please review your Privacy Preferences

Design and manufacturing process

Our design process begins with developing chocolate machines and related equipment using advanced solid modeling software. This allows us to thoroughly analyze each component, identifying potential manufacturing challenges, part intersections, and assembly issues before production begins.

Following this inspection, we implement the necessary design corrections and transfer all part data into an Excel-based environment. Thanks to a custom script we have developed, the system automatically categorizes and organizes components into four main groups: standard parts, sheet metal parts, weldment/routing parts (such as pipes, profiles, HVAC, PPRC, etc.), and production parts. This structured approach ensures efficiency, accuracy, and consistency throughout the manufacturing process.

This content is blocked.

Please review your Privacy Preferences

To streamline our purchasing process and minimize errors, we not only separate parts into groups using our custom script but also arrange them according to specific criteria such as sheet metal thickness or supplier name. The accompanying video demonstrates the very first operation we carry out at AkayGAM LLC after completing a design.

At AkayGAM LLC, we rely on professional tools to execute tasks efficiently, accurately, and with speed. In every machine design, we emphasize quality, functionality, and aesthetics. A key element of this workflow is the BOM (Bill of Materials), which we have customized to suit our needs. This system greatly simplifies material tracking and purchasing, enabling us to follow operations quickly and precisely. However, the BOM alone is not sufficient. For true efficiency, a robust standard part library is essential—and we have been continuously expanding and updating ours.

Each designed part and every standard component is assigned a product code, supplier details, and other essential information embedded directly within the file. This structured approach, combined with our flexibility and professional oversight across design, procurement, and manufacturing, is what sets AkayGAM apart from other manufacturers.

Modular Design

In the Design and Manufacturing Process section, we explained how machines are built from individual parts that are grouped together to form larger assemblies. At AkayGAM LLC, we place special emphasis on modularity to ensure that machines are not only robust but also easy to assemble and disassemble. For this reason, each machine is designed as a collection of groups that can be separated when needed.

This modular approach offers significant advantages during loading, shipping, and maintenance. Even though we take height and size constraints into account during the design phase, certain projects may still present challenges. In such cases, specific groups within the machine can be disassembled, allowing for easier container loading or quick access during servicing.

Software and operation

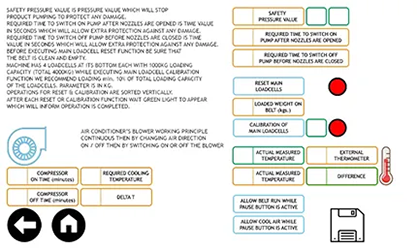

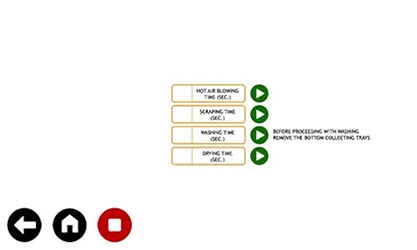

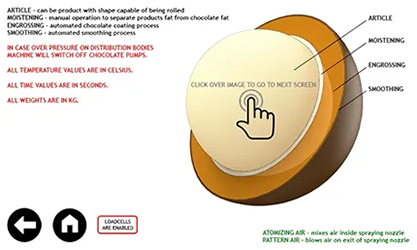

In terms of programming and operation, we maintain the same level of precision as in design, procurement, and production. Our equipment provides users with a wide range of configurable parameters, ensuring that machine operation is flexible and never limited.

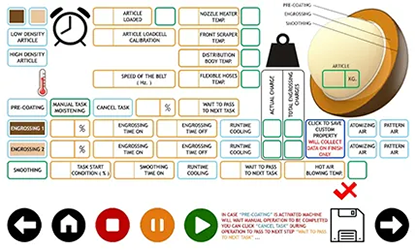

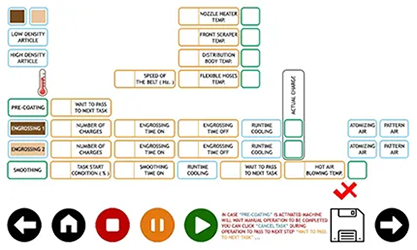

For HMI (Human-Machine Interface) design, we use a color-coded system: orange, blue/red, and green cells, with each cell clearly labeled to indicate its function. This intuitive layout helps operators understand and control the machines quickly and accurately.

- Orange cells: represent configurable parameters.

- Blue cells: indicate inactive operations.

- Red cells: indicate active operations.

- Green cells: display instructions or guidance for the operator.

For examples of the screen design, please refer to the adjacent images.

User Manual

The User Manual complements the topics described above and is designed to ensure that our customers can operate their purchased equipment independently, without requiring assistance from the manufacturer. To view a sample user manual, please click the button below.

USER MANUAL SAMPLECertificates

When exporting our products, we ensure that our customers can clear goods through customs smoothly and without any delays. To facilitate this, we provide not only movement certificates but also prepare and supply any additional certificates required for hassle-free shipping.